Hungry Eyes. That was my youngest sister’s nickname growing up because she’d always order the biggest thing on the menu and then not be able to finish it.

Huuuuungry Eyes,

One look at you and I can’t disguise, I’ve got…

Huuuuungry eyyyyyes.

I feel the magic between you and I…

The song is stuck in your head now, isn’t it? You’re welcome. What? It was a good song and even better in the movie, amiright or amiright? #nobodyputsbabyinacorner

When I designed this workbench, I knew I wanted to be able to fit a full sheet of plywood on it, so I made it massive at 4 feet wide by 8 feet long. And now that it’s complete, I’m re-thinking my decision to make it so enormous. Now I need a bigger garage.

Just call me ‘Hungry Eyes.’

This was a super simple and very quick build with a few clever features added. The materials list is pretty straightforward – a few 2×4 studs and three sheets of plywood or MDF are all you need. The cost for this bench runs about $100 in lumber. Because I chose the nicest, prettiest plywood, Purebond Plywood, my cost was closer to $150. What can I say? I have my priorities.

This was a super simple and very quick build with a few clever features added. The materials list is pretty straightforward – a few 2×4 studs and three sheets of plywood or MDF are all you need. The cost for this bench runs about $100 in lumber. Because I chose the nicest, prettiest plywood, Purebond Plywood, my cost was closer to $150. What can I say? I have my priorities.

*This post contains affiliate links. To read my full disclosure policy, click here.

Whenever I’m building, my workspace gets so overcrowded with tools and materials that I no longer have space to work. I find myself wasting time clearing off the mess I made before I can continue working. Inspired by the ingenious Paulk workbench, I added this second shallow shelf so that my tools and things are still within arm’s reach, without cluttering up the top of my workspace. The bottom shelf can hold scrap lumber and other larger tools.

Another handy feature I added was a couple of these magnetic strips to hold screws, drill bits, tools, and other miscellaneous (magnetic) things.

The workbench is the same height as my table saw, so it can also serve as an out-feed table for the saw. The workbench is on locking swivel casters so it’s easily movable and manageable, despite the size of this beast.

The workbench is the same height as my table saw, so it can also serve as an out-feed table for the saw. The workbench is on locking swivel casters so it’s easily movable and manageable, despite the size of this beast.

Pretty neat, right? Okay, so let’s get on with the tutorial!

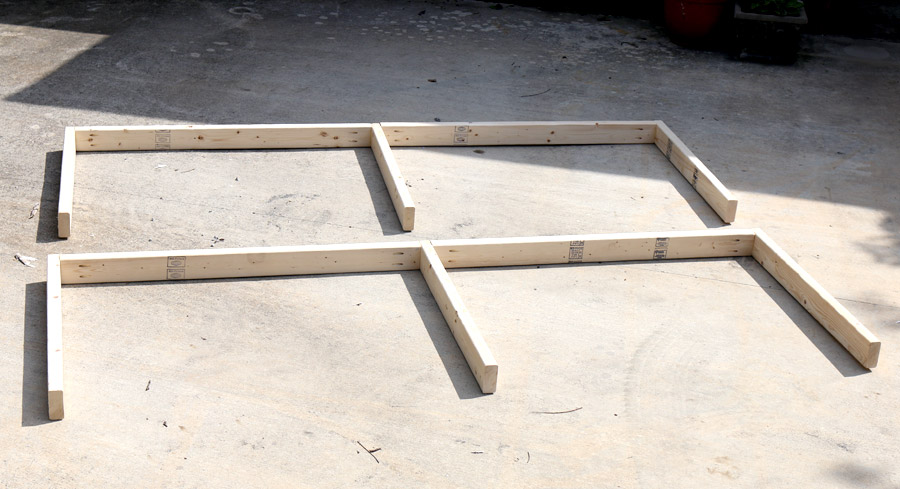

First, I built a couple of gigantic letter E’s. I used pocket hole joinery for this. This is the Kreg Jig I use and love.

Then I built the carcass with 2-1/2″ pocket hole screws and wood glue.

Then I built the carcass with 2-1/2″ pocket hole screws and wood glue.

Next, I notched out spaces in the plywood with my jigsaw so the legs would fit in nicely.

Next, I notched out spaces in the plywood with my jigsaw so the legs would fit in nicely.

Then I dropped the plywood into place and secured it with 1-1/4″ deck screws. Bottom shelf: done!

Then I dropped the plywood into place and secured it with 1-1/4″ deck screws. Bottom shelf: done!

Before I could move on, my 2- and 4-year-old decided it was their stage/tricycle track.

Before I could move on, my 2- and 4-year-old decided it was their stage/tricycle track.

It’s a good thing they’re cute.

Before the workbench got too heavy, I decided to attach the casters. I used lag bolts to secure the 3″ locking swivel casters to the bottom. The casters in the middle are non-locking.

Before the workbench got too heavy, I decided to attach the casters. I used lag bolts to secure the 3″ locking swivel casters to the bottom. The casters in the middle are non-locking.

Then I built the second shelf frame just as I did with the bottom.

Then I built the second shelf frame just as I did with the bottom.

Same thing with the plywood here too – notch out the leg spaces, drop in the plywood, and attach it with 1-1/4″ deck screws.

Same thing with the plywood here too – notch out the leg spaces, drop in the plywood, and attach it with 1-1/4″ deck screws.

For the two bottom shelves, I cut the plywood down a couple inches on two sides because I wanted it to sit flush to the frame, with no overhang. I did this with my table saw, but you could easily use a circular saw with a Kreg Rip-Cut. If you use a circular saw, I’d recommend switching out the blade to a plywood/OSB blade to minimize tear-out in your plywood.

It was quite a challenge to rip and cut a full sheet of plywood without an out-feed table, so I know this workbench will be very useful after it’s built.

This thing is super sturdy – solid as a rock, see?

This thing is super sturdy – solid as a rock, see?

Then I moved onto the top – building out the frame like I did the previous ones.

Then I moved onto the top – building out the frame like I did the previous ones.

This time, I didn’t have to cut the plywood at all. I just laid it on top, allowing for an inch overhang on all the sides, then attached it with 1-1/4″ deck screws. I didn’t use glue here because once the top gets too buggered up from working on it, I can easily remove the old top and replace it with a new sheet of plywood.

This time, I didn’t have to cut the plywood at all. I just laid it on top, allowing for an inch overhang on all the sides, then attached it with 1-1/4″ deck screws. I didn’t use glue here because once the top gets too buggered up from working on it, I can easily remove the old top and replace it with a new sheet of plywood.

I just love this shallow second shelf – super useful!

I just love this shallow second shelf – super useful!

When I look at this behemoth of a workbench, the song starts playing in my head:

When I look at this behemoth of a workbench, the song starts playing in my head:

One look at you and I can’t disguise, I’ve got…

Huuuuungry Eyes…

I feel the magic between you and I.

I’ve got hungry eyes for all the projects just waiting to be tackled. I. Am. So. Excited.

If you’d like to build this for your own workshop, I’ve drawn up the step-by-step plans for you!

I would love for you to pin and share this DIY workbench using the image below! Thank you and happy building!

WOW!! Jen that is amazing. I see some fun times in your future building on that workbench. The size is amazing. Now the trick is to keep it uncluttered. I would have that piled high with tools in no time!!

Thanks Crissie! That’s what that second shelf is for – to keep the clutter off the top. 🙂

I love this workbench! Perfect for an outfeed table and more. I need to build one of these. And get a better tablesaw;)

What software is used to make the detailed plans? Need to use it for my plans.

I use Google Sketchup to draw up my plans. There’s a free version!

Hi Jen, your workbench is amazingly functional and simple to make. Thank you so much for the plan and all the cute pictures. I really enjoyed them, very clear and easy to follow! I started to read your blog via anawhites, you become one of my fav bloggers now! I have a question about the lag bolts, is there any reason of using lag bolts instead of regular screws? Thanks!!

Thanks Ivy! I’m so glad you found your way here! 🙂 I used lag bolts because regular screws would have slipped through the opening on the casters. The lag bolts have a much larger, hex-shaped head that is bigger than the hole in the casters so it stays put. And I think it’s a heavier-duty option, so I went with lag bolts. Hope that helps!

thanks so much, Jen for your explanation. It really helps. I think I will just order what you used and follow your plan to build mine, except I will make it 2×12 to fit my space. I am still a newbie, may I ask a silly question, is there any benefit to overhung an inch on each side of the top?

No, I just like the look of it and also it allows me to “cheat” if the table isn’t perfectly square. Good luck and I’d love to see your bench when you’re done, so please tag me (@jenwoodhouse #jenwoodhouse) if you post it on social media! 🙂

Clamping, ladies, clamping! On a woodworking work bench, you want overhang (actually more like 2″) for clamping pieces during build up.

While I am new to the kreg pocket screws thing (Christmas gifts!), I’d have never thought to use them on a workbench. Nicely done! I would do one thing differently — use a continuous 2×4 for the long bottom rails, rather than splitting it and fastening to the center verticals. It would be stronger that way. And for the top as well.

Hi Peter,

I’m able to clamp without issues. Good point on the continuous 2×4 rails – if I were building this again, I’d definitely choose that route. Thanks for the comment!

I wonder how it works in conjunction with the table saw lift system ?

I just found your site and found it quite interesting.

With this plan for the Work Bench does it work well with a woodworking clamp?

Thanks! Yes, I clamp things to the bench all the time!

Thanks for the guide, i made mine 30×48 to fit my basement shop and its wonderful. I saw your project through a kreg email and nexi think i might attempt something like your printer table with the glaze. Wonderful plans and photos really helped this newbie!

Thanks so much Mike! Glad you stopped by!

Wonderful project! And the best part is your upbeat style, to many posters present things like a distasteful high school shop project, or that last 1 mile walk. This type of project will bring more folks into woodworking. Going back to an older post of a single (under 5′ round) ubit for holding power tools, this would work well as an extender. Thanks

Best Lew

Very nice, I want to build one

Hello Jen

Please help so I try to made this but boy oh boy major issue the guy at lowes cut everything wrong, I have 3 sheetwood at 5 feet 1 inch and 3 feet 1 inch and 27 2*4 now I have 6 legs at 3 feet 5 inch and all rails are 2 feet 10 inch so of course it don’t fit , can you please tell me what to cut the rails down to make it fit the sheetwood tops….THANKS IN ADVANCE BEEN WORKING ON IT FOR TWO DAYS

Just finished building this workbench. Fantastic build.

Purchasing a new Ridgid table saw (just like yours) this weekend. Looking forward to the use.

Awesome! Thanks for the kind words, Ben!

GREAT PROJECT! I love how happy you and your kids look!

How do like the Rigid Table Saw? How does your outfeed table match up? What would you suggest to do differently now?

Thanks TJ! I love my Ridgid table saw – the outfeed table is the perfect height. If I were to build it again, I think I’d make it half the width – I ended up using only half of the table anyway.