You guyyyyyys! I cannot tell you how excited I am to share my latest project with you! It has definitely been the most challenging (but favorite!) build yet!

Okay, so let me give you a quick rundown before we jump with both feet in: in case you missed it, here’s part 1 and part 2 of the Bar Cabinet Brainstorm.

So, where we left off last, the Hubs asked me to build him a place for his scotch decanters and I was lusting over this Restoration Hardware Printmaker’s Sideboard:

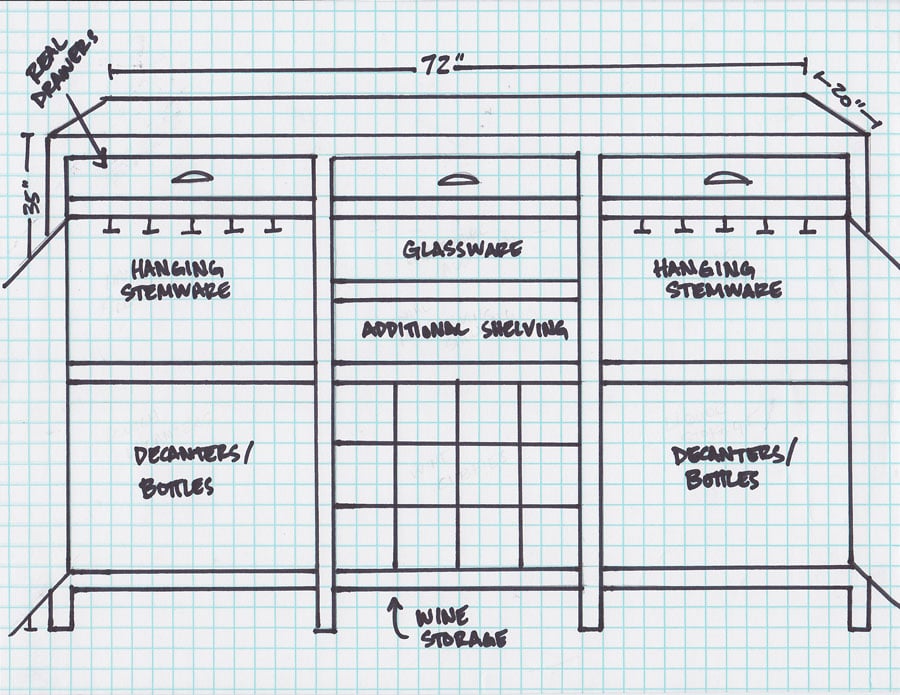

But instead of a bunch of shallow drawers, I wanted it to work as a bar by having some faux-front drawer face cabinet space (hey, that rhymed!) included, like this:

*This post contains affiliate links. To read my full disclosure policy, click here.

But sadly, I am not a plan-maker. I’m just an idea girl in desperate need of Ana White’s expertise and guidance. So I called on my sweet friend and she came to my rescue with these amazing plans! Be sure to pop over to Ana’s site – you can get the free plans to make your own Restoration Hardware knockoff Printmakers Sideboard! Pretty awesome, right?!

Okay, so I know I’ve been talking up the Kreg Jig with each build I do, but I really couldn’t have built this without it. It’s definitely been one of the best tool investments I’ve made. I used wood glue on all my joints and hid all the screws with the pocket holes. First, I built the front and back frames out of inexpensive 2×2 furring strips. I was at the lumber store for several hours (yes, hours!) sorting through the pile because it’s imperative to use the straightest boards possible.

Then I built the doors out of alternating 1x2s and 1x3s:

Then I quickly did a dry fit just to see how things would come together:

Then I joined the front and back frames with more 2x2s:

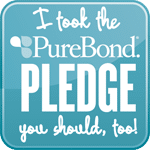

I used PureBond birch plywood for the bottom and side panels. Home Depot sells the PureBond brand. I was really excited about this product because unlike most plywood, PureBond plywood is environmentally friendly in that they use a soy-based, non-toxic adhesive to bind the real-wood layers together, whereas other plywood products, like particleboard or MDF, contain urea-formaldehyde in the glue which off-gas toxic carcinogens. Yikes! Since this piece will be living in our home for many years to come, I want to limit those hazardous materials as much as possible and provide the healthiest options for my family.

I installed the bottom panel by turning the whole piece on its side and zipping in the screws into the pre-drilled pocket holes. I’ve discovered it’s easiest to drill downwards and use gravity to my advantage.

Here are the bottom and side panels attached to the frame:

The top 3 drawers are real drawers, so I attached some 1×2 boards to support the drawer slides:

Then I built the drawers, putting the pocket holes on the outside because they would be hidden by the drawer faces.

Building a piece with drawers was challenging, to say the least. This was my first rodeo working with drawers and drawer slides and there were more than a few foot-stomping moments, I’ll admit. Here’s the most important thing about building drawers: make sure you check that they are SQUARE! If they’re not square, you’ll run into problems later (wonky drawers that don’t fit, align onto the drawer slides, or slide in and out smoothly). And even if your drawers are square, you still may have problems if the space you’re putting them in isn’t square. Needless to say, even after my meticulous measuring, cutting, and building, my drawers were still a little frustrating to deal with. Also, you may want to deviate from the plan and measure the drawer space and build accordingly, just to be sure they’ll fit. Each of my drawers fits a specific space, as in, I can only put the middle drawer in the middle space. One more thing worth mentioning: SHIMS! Pick up a package of shims (they’re really inexpensive) because they are the stuff of carpentry magic! I used shims on 2 of my 3 drawers to square them up and make them slide smoothly.

Holy moly, the drawers are in! And they actually work! Hallelujah!

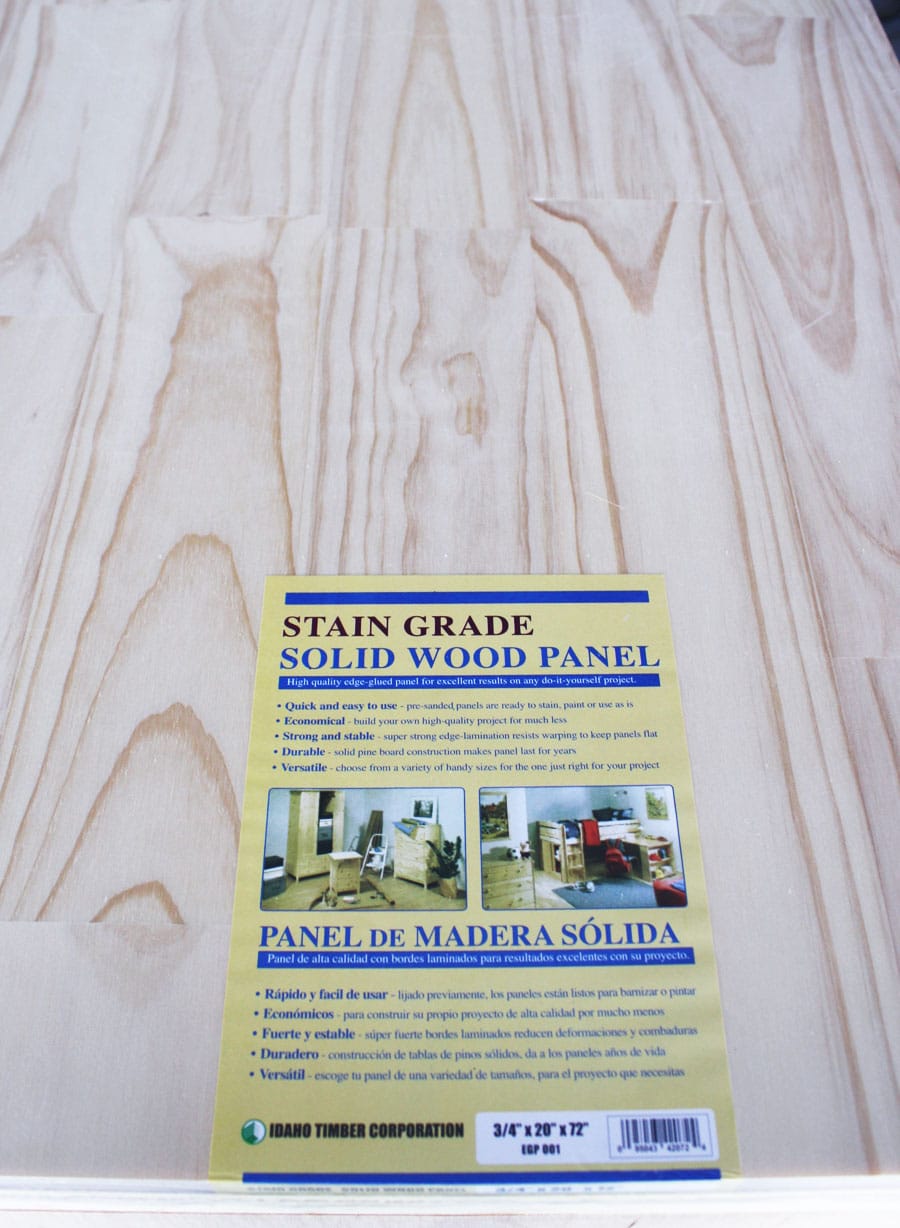

I had the lumber guys rip my plywood for me, but their measurements weren’t exactly accurate, so I was left with a board that didn’t fit on the top correctly. So, instead of purchasing another piece of plywood and making the same mistake, I bought this ready-cut solid wood panel:

Here she is: ready to be sanded and stained! By the way, I just laid the top on for the photo op (it’s not screwed in yet). I won’t attach it to the rest of the piece until the doors are on and everything is stained. It just makes for easier access (that’s what she said).

After filling the visible pocket holes with wood filler, I sanded the entire piece with 60 grit sandpaper, then followed up with a finer, 320 grit sandpaper. I vacuumed up the sawdust then wiped everything down with a damp rag. I chose Rustoleum Ultimate Wood Stain in Early American because it dries in an hour! I applied the stain with a foam brush, working in sections, wiping off the excess with a clean rag after about 2-3 minutes.

Aren’t these drawer pulls cool? I love their rustic, industrial look. I got them from this seller on Amazon for $2.25 each! I’ve seen them sold elsewhere for much more, so I was psyched to have snagged such a deal! I lined up each drawer pull perfectly using a chalk line reel.

It was much easier to stain each piece separately, before I assembled everything because that meant I wouldn’t have to contort my body in unnatural ways to get every nook and cranny stained evenly. Good thing, too, because you do not want to see a 9-month pregnant lady in such compromising positions. Take my word for it: it ain’t pretty.

After the stain was dry and I applied 3 coats of satin polyurethane, it was finally time to put it all together! The Hubs helped me attach the doors because it takes 2 sets of hands to hold the door and drill the hinges in place. Then, we screwed the tabletop onto the frame. So fun! It’s all coming together!

After letting it air out in the garage for about a week, we brought her inside. And here she is: all finished and ready to serve!

I’m in la-la-la-love (oh, yeah, and the Hubs is happy too)!

I also installed some shelving, a hanging stemware rack, and built a wine grid for the insides, so I’ll be back to share those details with you soon. Until then, you can download the free plans for this knockoff Restoration Hardware sideboard at Ana’s site. Thank you so much, Ana!

So beautiful Jen! You inspire me. Thank you so much for working with me on this project!

No, no, thank YOU, Ana! I seriously loved every second of this project. So fun!

I LOVE THIS! The finish is excellent.

Wow~ that’s gorgeous! You did such a great job!

Great job Jenn:)). I love it and love that you finished it just like my printers cabinet!! They make a perfect match:))

I know! I absolutely love your knockoff Anthropologie cabinet! So beautiful!

Wow! Jen I am so impressed, I have been checking out your blog for a while now, I saw some of your comments on Shanty2Chic, and of course your projects on Ana-white.com. This is beautiful! Best of luck with your sweet new baby!

Thanks, Mindi! The Shanty girls and Ana are all inspirations. I love them!

Wow! I want one too. I think you sold me on staining…I’m freaked out to stain furniture because paint hides all of mistakes so well. Did you have any huge issues with the staining process?

The directions on the can say to wait 15 minutes before wiping off the excess, but I’ve discovered it dries too quickly and gets too tacky to manipulate, so I wipe off the excess almost immediately to get the most even stain. Good luck!

So beautiful!! And, welcome back! Did Baby Boy make his entrance?!?!?

He did! I couldn’t have asked for a better childbirth experience. I’ll be back shortly to share Liam’s birth story!

Absolutely amazing. Is it totally crass of me to ask how much it cost do do it yourself?

Not at all! All the materials cost about $350. A far cry from RH’s $1300 price tag!

Hey Jen, This is a-mazing! Can I just ask what kinds of hinges you used? I like that you can’t really see them, and I was wondering what type they were.

Thanks and congrats on the new addition to your family!

Thanks, Lea! I can’t remember the exact brand name or model of hinge, but they’re inset cabinet hinges. I got them at Home Depot for about $6/pkg of 2 and they look like this:

http://www.homedepot.com/Tools-Hardware-Hardware-Cabinet-Furniture-Hardware-Cabinet-Hardware-Cabinet-Hinges/h_d1/N-5yc1vZc29a/R-100176398/h_d2/ProductDisplay?catalogId=10053&langId=-1&storeId=10051#.UGspOEJgPzI

Thanks!

I’m blown away at this piece. I have recently been inspired by Ana and have made a few RH copy cat’s including a coffee table on casters. This however, is IMPRESSIVE. I can’t WAIT to begin this project. I do have a few questions…

1. How exactly did you screw the tabletop onto the frame? Where did you screw?

2. When attaching the faces of the drawers, Ana’s instructions are confusing. Use a nailer, then glue, then screw from the inside??? Once again are you using jig? Where are you gluing? Can you go over exactly how you attached the faces? Thanks!!!

Thanks, Lauren!

1. We deviated from the plan with the top. Because my plywood didn’t fit inset like it was supposed to, I just bought a ready-to-stain panel and laid it on top, then screwed it from the bottom of the 2×2 frame. Per the plans, though, the top panel lies inside the frame and you attach it with pocket holes from all sides.

2. For the drawer faces, I just used glue and finish nails. Then I used a nail punch to hide the nail holes. I installed the pulls first before putting the face on. That’s probably what Ana meant, because you screw the pulls from the inside of the drawer face. Be sure to countersink, though, otherwise the drawer face won’t lie flush to the drawer.

Hope that helps!

Also, what is the name or style of the type of drawer pulls?

The brand of the pulls is Hickory Hardware. Here’s the link to the exact pulls I used:

http://www.amazon.com/Hickory-Hardware-P3004-BI-3-Inch-Refined/dp/B000N8IWZE/ref=sr_1_3?ie=UTF8&qid=1348173499&sr=8-3&keywords=hickory+hardware+pulls

Hope that helps!

Thanks! Phew!!! I ordered the right ones!!!!!! Oh…minus the time you let the finished piece sit in the garage, about how long does it take to build this piece? Congratulations on the new baby! Hopefully you will feel human again real soon. I know what you’re going through (I have four of my own, my youngest two just turned 1& 2 – at only 14 months apart)…good luck!

I’d guess it took me about 15-20 hours to build, but I had to take breaks and build during nap times and weekends. You probably could get it done quicker if you devote a full weekend to it. Good luck! Come back and share pics when you’re done!

Wow, this is amazing. Saw it on Pinterest and had to pop over here to find out more. Now I’m off to check out your other projects!

Thanks for visiting!

Hello, it’s me again. I’ve purchased my table saw and Kreg Jig and I’m totally legit! Wish I could buy knowledge…I’m a little confused on the settings for the Kreg Jig for the frames. I’m setting my board thickness on the Kreg Jig and it seems it doesn’t go beyond 1 1/2″ on the top and 1 3/8″ on the bottom for the screw bit. Since the furring strips are 2×2″…it seems I will have to guess where to set the stop on the drill bit and the top. Plus, boards are never the thickness they say they are! Maddening! So…wondering if you can tell me where to set the thickness for both the top adjustable portion and the large screw bit. Thanks in advance!!!

Yay for new tools! The Kreg booklet tells you what setting and which length screws to use for the specific width of material. And yes, boards are usually 1/2″ smaller than what they’re called (2×2 is actually 1.5″ wide).

I just measured the 2×2 strips…and they are 1 1/2″ thick. Sorry for asking, I should have just done that first. I am curious, did you put your drill bit into A,B or C?

It doesn’t matter, I just try to space the pocket holes about 6-8 inches apart.

Very cool and I love that you made it. The bin pull handles are the perfect touch.

You rock! This is gorgeous, Jen! {and no…I haven’t broken out the Kreg. Yet.} lol!

Thanks so much for sharing your creativity and awesome talent. I always leave here inspired!

Aw, thanks so much, Roeshel!

Just realized this piece doesn’t have a back??? Am I missing something?

Yes, you can use a 1/4″ piece of plywood for the back (see Step 13 in Ana’s plans).

I went to Lowe’s and the hardware guys were confused by what “inset hinges” are. They assumed they were the frameless hinges used on kitchen cabinet doors. Those are over $6 each and you have to use a special drill bit to cut a circle into the wood to accommodate the inset portion of the hinge. Are these the right ones? Is there any way to can take a picture of your installed door hinges? Also, Ana’s supplies and cut list don’t include that small piece of wood running along the backside of the piece, which (I’m assuming) supports the drawers. Is that a 1×2? Is that suppose to help stop or support the back of the drawer?

I can’t remember the exact brand name or model of hinge, but they’re inset cabinet hinges. I got them at Home Depot for about $6/pkg of 2 and they look like this:

http://www.homedepot.com/Tools-Hardware-Hardware-Cabinet-Furniture-Hardware-Cabinet-Hardware-Cabinet-Hinges/h_d1/N-5yc1vZc29a/R-100176398/h_d2/ProductDisplay?catalogId=10053&langId=-1&storeId=10051#.UGspOEJgPzI

Thank you! Those look considerably smaller than the ones I got. I’ll head to Home Depot and get these! I’ve been working on the drawers today, and they are a doozie. It’s taken 3 hours to successfully install one drawer. I was so sick of the guesswork, so I went ahead and nailed the face onto the drawer, then installed to the box. My question about this is, I hadn’t installed the handles yet…I thought the rounded screw heads that hold the handle in place wouldn’t allow the face to lay flush to the front of the drawer. Hoping one of my hardware stores will sell these handle screws, but longer, so I can attach the handles. Ugh…this project is not for the faint of heart.

The screws for the pulls won’t be flush unless you countersink the screws. Good luck!