The majority of my DIY projects are borne out of necessity and my latest build is no exception. My newlywed friends Josh and Marie needed a desk for their apartment. Josh is in seminary and is having to do his homework on their bed or on the floor.

Most recently, he set up this ingenious solution:

Pretty sweet, right?

Pretty sweet, right?

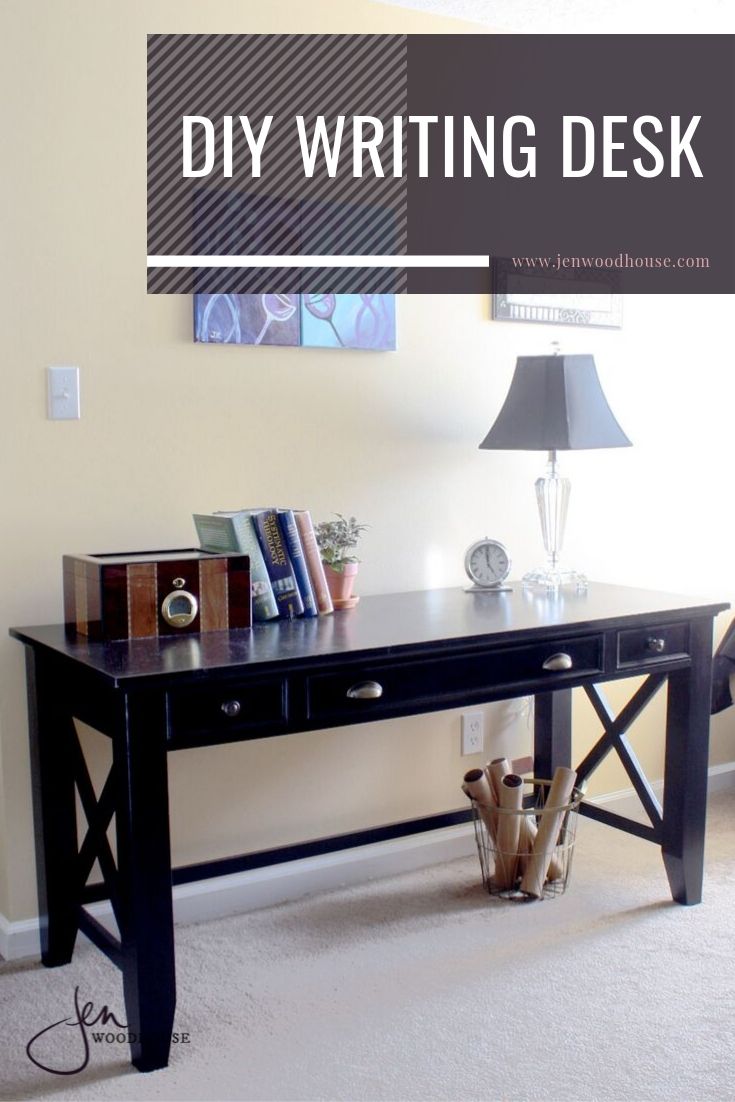

Sadly, this ironing-board-turned-desk was not going to work as a permanent solution so they came to me and asked if I would build them a simple writer’s desk. Of course I said yes! I jump at any chance to build something new and making this desk for them was a blessing to me. After brainstorming some ideas based on their needs and wants, we came up with this design:

Several weeks later, Josh has happily relegated his ironing board back to its original, intended use.

Several weeks later, Josh has happily relegated his ironing board back to its original, intended use.

*This post contains affiliate links. To read my full disclosure policy, click here.

*This post contains affiliate links. To read my full disclosure policy, click here.

I’m excited to share the plans and tutorial with you today so you can build your own DIY Writing Desk!

Click here to download the Ehlers Writing Desk PDF Plans.

I teamed up with my friends at Osborne Wood to design and create these pretty tapered legs. The legs were custom, but are now available for sale here. I chose the knotty pine species, at about $20/leg.

Once again, I chose to build with my favorite plywood ever, Purebond Plywood. I bought mine from The Home Depot. It’s the prettiest plywood I’ve seen on the market and it’s formaldehyde-free. Read about why Purebond is the healthier alternative here.

Okay, so let’s get started, shall we?

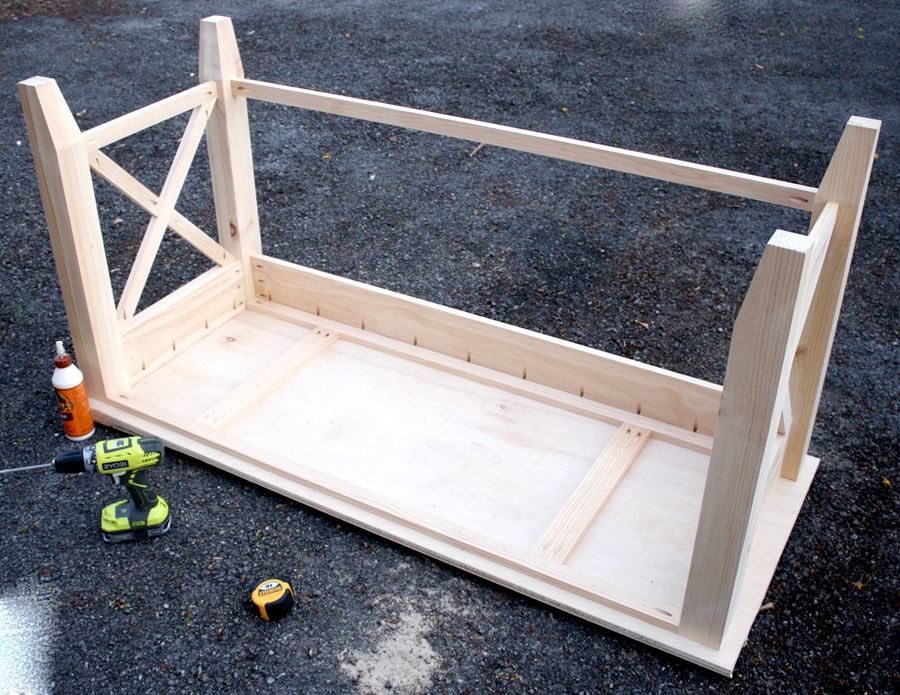

First I built the sides and legs. I drilled 3/4″ pocket holes like so and attached the sides to the legs with 1-1/4″ pocket hole screws.

If you’re not familiar with pocket hole joinery, I use the Kreg Jig K4 Pocket Hole System to drill these holes. In a nutshell, this jig allows you to drill pocket holes at just the correct angle to create a strong joint. I prefer using pocket hole joinery whenever possible because it makes joining wood super easy. No need to bother with fancy woodworking joinery methods like mortise and tenons, biscuits, dovetails, and the like. And you can drill the holes on the insides of the boards, so they’re hidden.

Don’t forget to drill pocket holes facing up to attach the top in later steps.

Then I added the cross pieces. There are measurements in the plan, but I recommend cutting it to fit your specific build to ensure precision. I don’t use a tape measure here, I just hold the 1×2 board up and mark it in place, then cut it to fit.

Then I added the cross pieces. There are measurements in the plan, but I recommend cutting it to fit your specific build to ensure precision. I don’t use a tape measure here, I just hold the 1×2 board up and mark it in place, then cut it to fit.

Here’s an inside and outside view of the sides:

Next, I constructed the carcass.

Next, I constructed the carcass.

Then I attached the top. Remember how I drilled pocket holes facing up? This is why.

Then I attached the top. Remember how I drilled pocket holes facing up? This is why.

I like to flip the desk upside down so that I’m using gravity to my advantage when drilling those pocket hole screws in. Work smarter, not harder. I laid a piece of scrap plywood down to protect the top from being marred by the gravel.

Now it’s time to start constructing the components for the drawers.

Now it’s time to start constructing the components for the drawers.

I chose to rip some plywood scrap pieces down to make the dividers where the drawer slides will be attached because it’s what I had on-hand. You can use solid wood boards if you’d like, you’ll just have to rip a 1×5 board down to 3-3/4″ width since a standard 1×4 board usually only measures 3-1/2″ wide.

I chose to rip some plywood scrap pieces down to make the dividers where the drawer slides will be attached because it’s what I had on-hand. You can use solid wood boards if you’d like, you’ll just have to rip a 1×5 board down to 3-3/4″ width since a standard 1×4 board usually only measures 3-1/2″ wide.

Now it’s time to build the drawers.

Now it’s time to build the drawers.

Build the drawer box by drilling 3/4″ pocket holes on the outsides of the boards (they’ll be hidden by the drawer face in later steps) and attaching with 1-1/4″ pocket hole screws. Remember to check the drawer box for square. To check for square, measure the two diagonals. These measurements should match. If they don’t, you can adjust the box by taking the longer measurement and squeezing them together until the measurements match. You can also clamp a speed square to the inside of the box before fastening the boards together.

Build the drawer box by drilling 3/4″ pocket holes on the outsides of the boards (they’ll be hidden by the drawer face in later steps) and attaching with 1-1/4″ pocket hole screws. Remember to check the drawer box for square. To check for square, measure the two diagonals. These measurements should match. If they don’t, you can adjust the box by taking the longer measurement and squeezing them together until the measurements match. You can also clamp a speed square to the inside of the box before fastening the boards together.

I built one of the side drawers a hair too wide, so instead of disassembling it and building it smaller, I called on my neighbor Josh to help me out (don’t get confused here – not Seminary Josh, this is a different Josh, he builds houses – no big deal. We’ll call him Builder Josh). Builder Josh came over with his hand planer and planed about 1/8″ off the sides so that the drawer would fit. Thank God for builder neighbor friends with very common first names.

I built one of the side drawers a hair too wide, so instead of disassembling it and building it smaller, I called on my neighbor Josh to help me out (don’t get confused here – not Seminary Josh, this is a different Josh, he builds houses – no big deal. We’ll call him Builder Josh). Builder Josh came over with his hand planer and planed about 1/8″ off the sides so that the drawer would fit. Thank God for builder neighbor friends with very common first names.

Builder Josh also helped me figure out this moulding business because cutting moulding can be so tricky! You guys. I could not, for the life of me, figure out how to wrap the cove moulding around the legs and sides. Once again, Builder Josh to the rescue. He does quite a bit of moulding work when he’s building houses, so I knew he’d be the perfect person to ask.

If you’re like me and you either 1) don’t want to bother with coping the moulding or 2) don’t own a coping saw, you can cut this piece of moulding on an inside miter, 45º angle like so:

Then attach the rest of the cove moulding so that it wraps around the legs. Again, I don’t use a tape measure here. Hold the trim in place, then mark it and cut it to fit.

Then attach the rest of the cove moulding so that it wraps around the legs. Again, I don’t use a tape measure here. Hold the trim in place, then mark it and cut it to fit.

You may need to cut it long and keep trimming it down until it fits perfectly. Or in my case, it goes like this: “too long, too long, too long… too short. Dangit!” And then you go back to store to buy more trim. It happens.

Then I attached the drawer faces and trimmed them out with some tiny trim, mitering the ends at a 45º angle.

Then I attached the drawer faces and trimmed them out with some tiny trim, mitering the ends at a 45º angle.

I got all the hardware from DLawless Hardware. Not only do they have a massive selection of knobs and pulls, but they sell metal drawer slides too!

I got all the hardware from DLawless Hardware. Not only do they have a massive selection of knobs and pulls, but they sell metal drawer slides too!

Aren’t these cup pulls beautiful? But don’t be fooled, they are a bear to install. Seriously, they were the most difficult part of this whole project. I wish I was kidding.

Aren’t these cup pulls beautiful? But don’t be fooled, they are a bear to install. Seriously, they were the most difficult part of this whole project. I wish I was kidding.

My husband had to install the cup pulls because he found me sitting under the desk, with a wild look in my eyes, a can of gasoline in one hand and a match in the other.

“Step away from the desk, Jen. Step away from the desk.”

Sometimes you just reach a point of diminishing returns, right? Thank God for husbands.

And a few finishing steps later, the desk is done!

And a few finishing steps later, the desk is done!

Here’s the finishing tutorial.

I’d love for you to pin and share this post by clicking the “pin it” button on the image below:

I’d love for you to pin and share this post by clicking the “pin it” button on the image below:

Disclosure: Osborne Wood created and provided the furniture legs and D. Lawless Hardware provided the hardware for this project. I was not told what to write or what project to complete; all efforts, happy dances, professions of undying love, and opinions are my own.

Pin for later!

It is gorgeous! I love the “before” too;) It reminds me of all of the makeshift stuff we had until we built the real thing! I wonder if I could build a wider version of this with drawers on each side for my husband and I to share. Our current desk situation is not ideal:)

Thanks, Katie! And definitely! I’d just build some kind of support (extra set of legs?) in the middle so it doesn’t sag.

What a great friend you are Jen!! What would they all do without you?! Hehe!! This is gorgeous and I’m glad Adam caught you in time and didn’t let you burn it to the ground!! Lol!! I need to build a desk and can’t decide what style to go with!! This is a contender!! Thanks for your amazing tutorials!!

You’re so welcome, Cara! Thanks for stopping by!

THE WRITING DESK IS A GREAT IMPROVEMENT OVER THE IRONING BOARD….BUT IF YOU ARE GOING TO JUMP INTO THIS TASK,… YOU SHOULD CONSIDER THE AGE OLD SLANT-TOP DESK IN CHERRY OR WALNUT OR WALNUT AND ASH DRAWERS, ETC.

THIS DESIGN GETS FRUSTRATING, CHALLENGES PATIENCE AND

SATISFIES THE NEED TO TAKE A BREAK TO MAKE A TRUE HEIRLOOM. FAMILIES FIGHT OVER THESE DECISIONS WHEN IT COMES TO INHERITANCE. WOODWORKERS ARE OF THE FIGHTING CLASS…..LET’S DO BATTLE. UNCBOB

Wow it is so beautiful!!! Amazing job Jen, glad your husband could help! Lol, it is amazing how the seemingly simple things can be the hardest! The plans look amazing as well, you are AWESOME!!!

Thanks for the kind words, Mindi!

That is one beautiful desk. I love the legs, I might have to get some of those. What a sweet way to bless your friends! They are lucky to call you friend. Have a blessed day.

Definitely! Osborne legs are so easy to build with! Thanks for stopping by, Crissie!

This desk is fabulous, great job. And the new blog design is awesome!!!

Thanks so much, Amy!

Great plans. I have a set of legs I got from my son off a table he was going to pitch. They are very similar to those you used. I’ve been wondering what to do with them and they are too pretty to pitch. Now I have an idea, and a grandchild on the way who will someday need a desk!

Hey there!! This desk is absolutely to die for! I’ve been looking for an affordable desk for a while and never thought of building one! The only problem is that I only have a 45″ space to work with… I will have to do some problem solving but I love this design!!

Thanks Katie! That’s the beauty of DIY – you can modify these plans (or any others) to fit your space. Good luck and happy building!

I have looked endlessly for a nice table for my computer. I really like this. I am ready to build! Can you tell me, though, about the drawer fronts? The seem to have a detail around the perimeter of each one yet no detail is discussed in the instructions. Nor, is anything called out in the parts list. I would positively love a close-up photo if one could be emailed to me. Would it also be possible to identify the paint color and brand? Thanks so much!

I am building this for my wife for an anniversary present. The plan is to do the top out of planks of 1″ x 4″ walnut but use your base design. Can’t wait to get into it. buying the wood this afternoon from my local mill. Thanks so much for the plans and inspiration!

This is fantastic, Jen. I’m a writer and woodworker and have been searching endlessly for something exactly like this. I have a nice old antique desk but it’s just not big enough to hold my laptop, separate 21 inch monitor and legal pad and leave room for me to move my Bluetooth mouse. I like the convenience of Kreg jig joinery for the hidden areas but will probably go for a little more elegance in exposed areas. I’ll likely opt for traditional mortise and tenon for the stretchers and half laps for the x braces. I’ll also need to adjust the sizes to fit my needs, but otherwise a top notch design – absolutely love it.

Thank you so much, Robert!

Finished this project at the beginning of the year and it turned out great! I included all my modifications and I couldn’t be happier. I have a large 52×20 workspace and it’s a beautiful addition to my home. Thanks again, you rock.

This design I liked a lot, so much that it was my last project finished, thanks for your ideas

Just built this for my wife for our 11 year anniversary! she love s the design and i loved building it for her. I made the top, drawer fronts and side X’s out of of black walnut which looked amazing. the legs that came from Osborne wood were perfect and delivered the next day! ( i live NE of Atlanta so they are just up the road.) Thank you for your easy to follow plans and inspiration.

Regards,

-Joe

Thanks for the lovely note, Joe! So happy to hear this!

What was the top made from?

Hi Tim,

The top is made with 3/4″ hardwood plywood.

I’ve been wanting to build this desk forever! I’ve had it saved on my pintrest board for years now and finally this weekend we are going to start building it! I am so excited to start this and see the completed work. My father in law who is a carpenter by trade was so impressed with your detailed prints. Thank you a million times over!

Yay! Thanks for the kind comment, Megan. I’m excited for you!

Hi Jen, I am preparing materials to build this beautiful desk, and have read through everything several times and do not see how to attach the X pieces on the sides, The directions simply say to attach them. Can you tell me how they are attached? From the top is too wide and from the bottom the angles are difficult to get through neatly….if we use pocket holes it doesn’t say where to put them. Thanks for your help and again, it is such beautiful work.

Hi Amy!

You’ll want to use pocket holes to attach the X pieces – you can see the pocket holes best in the photo that shows the “inside/outside view of the sides” – hope that helps! Good luck and happy building!