*This project is sponsored by The Home Depot.

My Oh My! I’ve had ants in my pants over this DIY Sliding Barn Door Loft Bed project for months now and I am SO EXCITED to finally share the plans and tutorial with you guys! Are you ready for this? Hunker down, friends, this is gonna be one ton of fun.

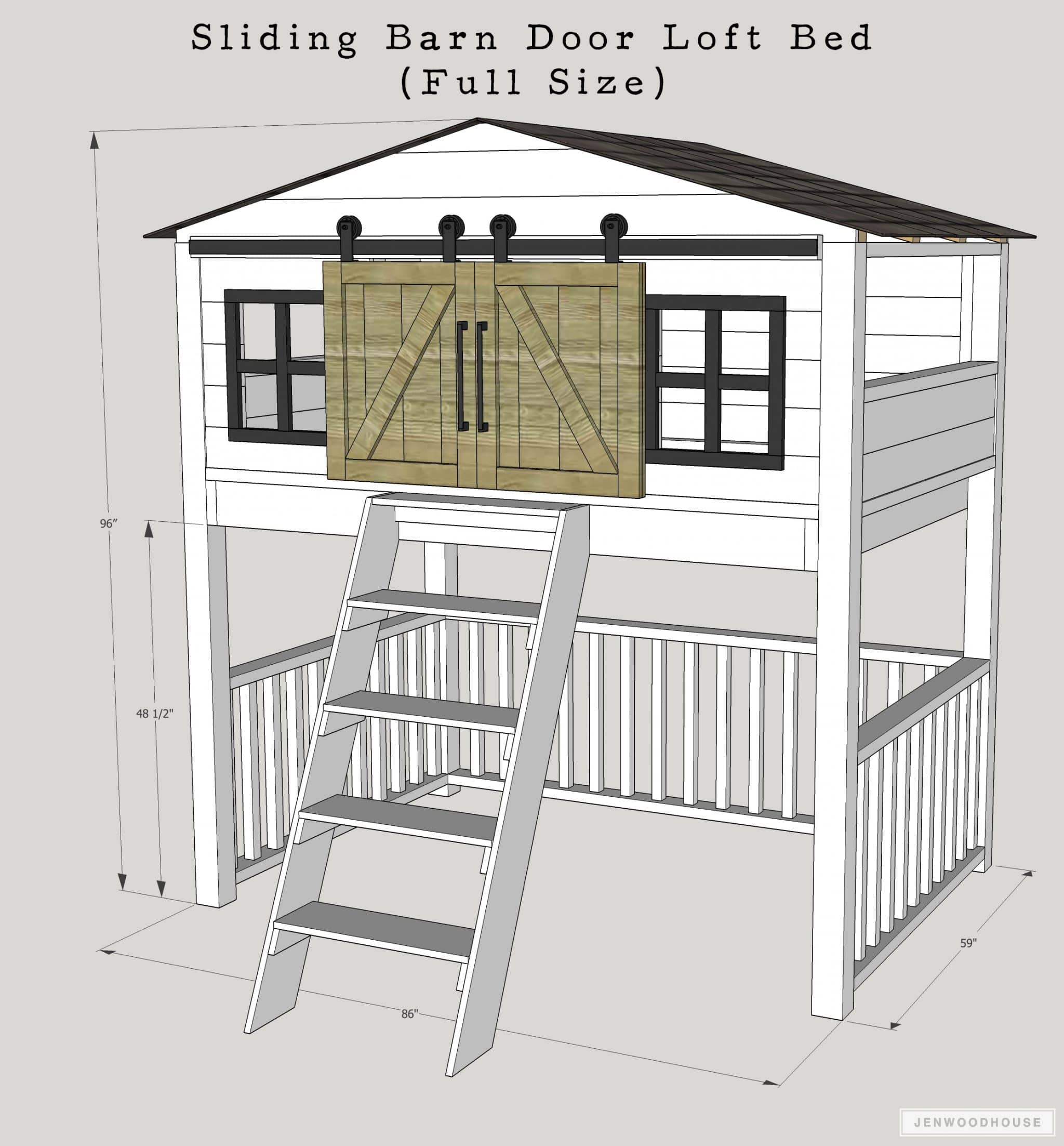

If you follow me on Instagram, you’ll have seen sneak peeks and behind-the-scenes footage as we were building this DIY sliding barn door loft bed. I saved the Instagram stories in my highlights, so feel free to check that out. By the way – this plan fits a full-size mattress and the total cost was about $550.00. Also, just for reference, we have 9-foot ceilings in this room.

If you follow me on Instagram, you’ll have seen sneak peeks and behind-the-scenes footage as we were building this DIY sliding barn door loft bed. I saved the Instagram stories in my highlights, so feel free to check that out. By the way – this plan fits a full-size mattress and the total cost was about $550.00. Also, just for reference, we have 9-foot ceilings in this room.

Do you want the cliff notes? Here’s how it’s gonna all shake out… and if you’re curious about the basics of staining and finishing wood, watch the videos at the end of this post!

Do you want the cliff notes? Here’s how it’s gonna all shake out… and if you’re curious about the basics of staining and finishing wood, watch the videos at the end of this post!

- Railings

- Side panels

- Front and back panels

- Mattress box

- Assembly

- Stairs

- Doors

- Roof

Hardware and Roofing Supplies:

- (1) Sliding Barn Door Hardware Set

- (2) Top Mount Hangers

- (6) Simpson Strong-Tie Fence Brackets

- (8) 3/8-inch x 5 1/2-inch Carriage Bolts

- (3) 3/8-inch Split Locking Washers 3-pack

- (1) 3/8-inch Zinc-Plated Steel Flat Washers 8-pack

- (4) 3/8-inch Zinc-Plated Cap Nuts 2-pack

- (3) Suntop 26-inch x 8 ft. Polycarbonate Corrugated Roof Panels in Castle Grey

- (1) Suntop 4-ft. Ridge Cap in Castle Grey

- (1) Woodtite 1-inch Fasteners 50 pcs.

- 2 1/2-inch and 1 1/4-inch Wood Screws

- 2 1/2-inch and 1 1/4-inch Pocket Screws

- 1 1/4-inch Brad Nails

How to build a DIY Sliding Barn Door Loft Bed

How to build a DIY Sliding Barn Door Loft Bed

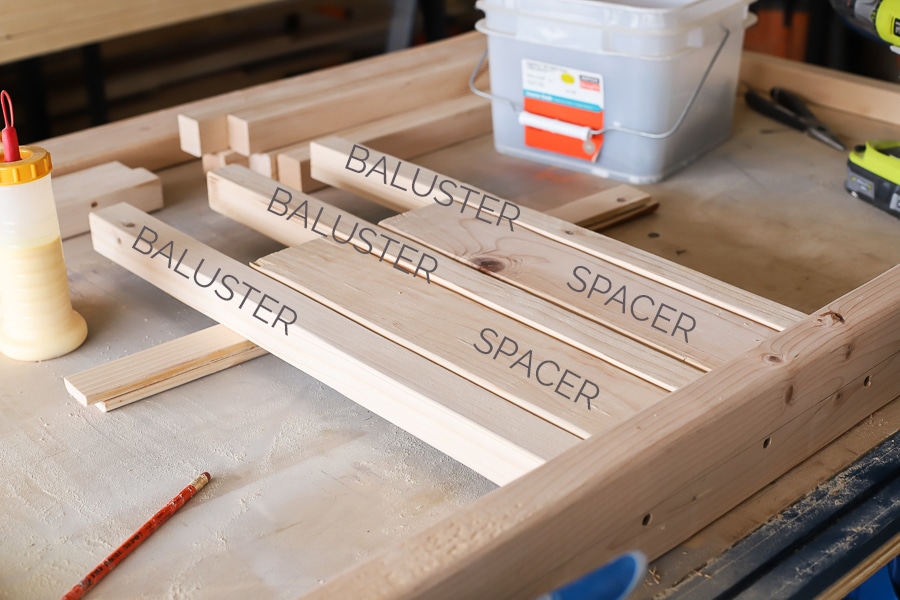

1. BUILD THE RAILINGS

You can purchase 2×2 lumber off-the-shelf, but we found it to be more cost-effective to rip down 2×4 studs to make the 2×2 balusters. We used a 2×4 spacer to evenly space the balusters 3 1/2 inches apart. Pre-drill pilot holes and countersink the 2 1/2-inch wood screws. It’s also a good idea to sand the balusters before you attach them.

Lather, rinse, repeat eleventy times.

Fill the screw holes with wood filler, then sand smooth.

2. BUILD THE SIDE PANELS

Does your Home Depot sell 2×3 lumber? My Texas store location does, but I could never find them when we lived in Alabama. If you can get your hands on some 2x3s, they’ll work best because they allow the tongue-and-groove boards to be slightly inset. In the photo below, the rails are 2x4s and the stiles are 2x3s. See the inset? Now you’ll be able to attach the 3/4-inch thick T&G boards and not have them stick out past the 2x4s.

Notice how the T&G boards fit nicely into place. Once you build the frame, you’ll just glue and nail the T&G boards in place – easy peasy.

The photo below shows one constructed side panel. You’ll build two of these, of course. These will end up being the headboard and footboard of the bed.

Special shoutout to my good friend and neighbor, Tamra. She’s a supermom to 6 kids (3 of which are triplets!), Army wife, and overall amazing friend. She’s been a Godsend. Tamra’s not only listened to me over-analyze, second-guess, and agonize over every part of this project, but she helped me sand and paint ALL THE THINGS. And there were so many things to be sanded and painted. She’s a trooper. Thank you, Tamra!

I built each component (railings, side panels, front and back panels, mattress box) separately, then brought everything into the room for assembly, but I’d recommend building as you go, if you can. No matter how accurate my measurements were, once Adam and I got the parts into the room, those pre-determined measurements changed and shifted as we put the bed together. So, if you can (and if you have the patience and time), build as you go. Meaning, build the two side panels and back railing, then take the completed side panels into the room, then attach the back railing. The side railings are permanently attached, while the back railing slides into place with these fence brackets. This makes disassembly much easier when it comes time to PCS (move). Measure the space for the mattress box, then build accordingly. Attach the mattress box to the legs, then measure the space for the front and back panels, then build for those dimensions… and so on and so forth. Make sense?

Because I built the side, front, and back panels beforehand, then tried to put it all together in the room, there was a lot of trial and error. We’d carry the front panel into the room, try to fit it into position, discovered it wouldn’t fit, then have to take it back out to the shop to shave the sides down with a hand planer and belt sander until the front panel fit into place. Same thing goes for the back panel.

My sweet husband. He lifts all the heavy things. Repeatedly. God bless him.

If you build as you go, you’ll be able to measure and then build to those measurements. If you choose to build the loft bed the way I did, just know that you’ll likely need to make adjustments along the way. I hope you have a sweet husband who lifts heavy things repeatedly too.

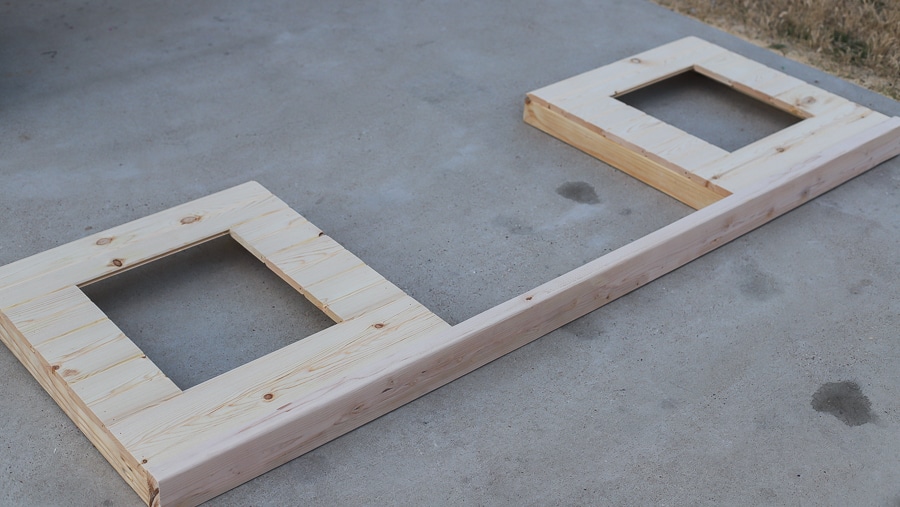

3. BUILD THE FRONT AND BACK PANELS

Same song and dance for this part too – the stiles are 2x3s while the rails are 2x4s, which allows space for the tongue-and-groove boards to be slightly inset from the 2×4 rail. Attach the T&G boards with glue and nails.

For the windows, I constructed the outer frame with pocket hole joinery and cut overlap joints for the muntins (the criss-cross part). The muntins were then attached to the frame with pocket screws. I cut the lap joints with several passes on the table saw. You can also use a circular saw for this – just be sure to set the depth of the cut so that you’re removing half the amount of material on both pieces so that when you join the two, you’ll have a flush surface.

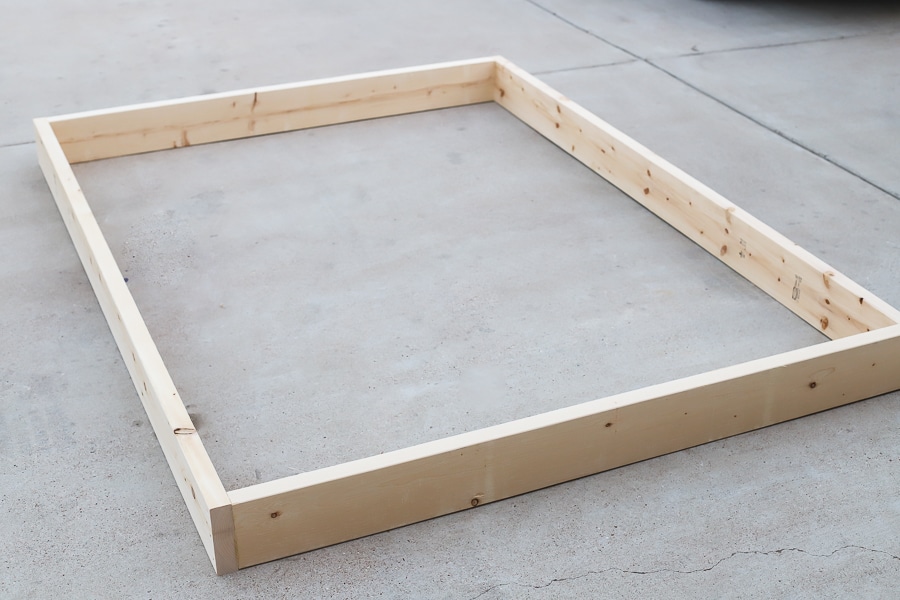

4. BUILD THE MATTRESS BOX

This part is pretty easy. First, you’ll build the box out of 2x6s and 2 1/2-inch wood screws. Check for square, adjust as necessary.

Next, you’ll attach the 2×3 mattress cleats to the sides of the bed box. Measure and mark the center point on the short ends and attach the fence brackets. These brackets will hold the center support so that the mattress doesn’t sag.

5. ASSEMBLY – ATTACH THE MATTRESS BOX TO THE LEGS

Bring the mattress box into the room and attach it to the 4×4 legs. This is where we used the carriage bolts, flat washers, split locking washers, and cap nuts. We pre-drilled the holes into the 4×4 legs and 2×6 mattress box, then inserted the carriage bolts, washers, and cap nuts. You’ll see where I had to carve out a space in the adjacent boards for the cap nuts. If you place your hardware further inward, you shouldn’t have this problem.

Once the mattress box is in place, you can measure and cut the 1×3 mattress slats and lay them in place. I spaced them about 5 1/2 inches apart (I used a scrap tongue-and-groove board as a spacer) and screwed them down with 1 1/4-inch wood screws. Be sure to pre-drill pilot holes so that you minimize the risk of the wood splitting.

This is also a good time to put the full-size mattress in – once you have all the walls attached, it’ll be a tough job to wrestle the mattress inside.

6. BUILD THE STAIRS

After hemming and hawing over whether to build stairs or a ladder, I finally decided to build stairs. I used 1×8 boards for this, which is plenty strong for the kiddos, but I feel a little uneasy when my husband puts his weight on these stairs. You may want to use 2×8 boards if you have trust issues like I do.

7. BUILD THE DOORS

I used leftover scrap tongue-and-groove boards and 1×3 mattress slats to build the doors. Measure, mark, and cut the T&G boards to length, plank them together, then attach the 1×3 boards on top with glue and nails. Simple enough. I used Varathane’s Golden Oak wood stain for the barn doors. Below, you’ll find a couple helpful videos on my staining and finishing process.

Installing the sliding barn door hardware was very straight-forward. The instructions that came with it were very easy to follow. Remember, the hardware set includes 2 hangers, so you’ll need to order 2 more because you need 4 total – 2 for each door. We did have to cut the metal rail down from 96 inches to 79 inches – we used an angle grinder for this, then used a file to remove any burrs and sharp edges and touched up the edges with black spray paint. We screwed the top mount hangers onto the doors, positioned and tightened the door stoppers, then hung the doors.

8. CUT THE ROOF PANELS AND ATTACH THE ROOF

Because this DIY sliding barn door loft bed already weighs a ton, I didn’t want to add too much more weight with the roof. I considered real shingles (too messy and gravelly), cedar shingles (not available in-store), plywood (more weight)… you name it, I probably considered it. I finally decided on these polycarbonate corrugated roof panels. They’re super light and come in different colors – you may even choose the translucent roof panels, if you want more light to come through. We chose the 8-foot panels in Castle Grey and used battery-powered RYOBI shears to cut it. You can also use a circular saw or even some heavy duty kitchen shears – the panels are plastic, so they’re super light and easy to work with.

We used these wood screws with foam washers to attach the roof panels to the rafters.

I kind of wish I would have either stained or painted these rafters. Oh, well. Hindsight is 20/20, isn’t it?

We also switched out the existing ceiling fan for this pretty flush mount light fixture. Isn’t it perfect?!

So… are you ready to build your own DIY Sliding Barn Door Loft Bed? I’ve got you covered with the plans! Hope you enjoy them – feel free to reach out if you have any questions along the way and please tag me on social media if you build this bed – I’d LOVE to see your versions! Happy building!

SHOP THIS POST

*This project is sponsored by The Home Depot. This post contains affiliate links. All expressed opinions and experiences are my own words. My post complies with the Word Of Mouth Marketing Association (WOMMA) Ethics Code and applicable Federal Trade Commission guidelines.

Hello! LOVE the bed! What handles did you use for the barn doors?

Where is the polka dot chair, round table-accessories from please? Thank You

Hi Maggie,

All the items are from The Home Depot!

Awesome bed! We’re excited to start building. What point in the process did you start your painting? And how many coats of paint do you think is needed? Thanks

Hi Gabe,

So exciting! I painted when the separate components were built (sides, front/back, etc.), before assembling the bed in the room. I’d recommend 3 coats.

Good luck and happy building!

Thanks. Also, I see that the mattress box is 56” wide. A standard full mattress is 54”, so it should fit fine. However, the 2×4 bottom rails of the front and back panels each cut in another 2”. This leaves an overall width of 52”. Were you able to fit a standard full size mattress in that? Thanks, Gabe

Gabe, I have the exact same issue. I’m building this x3 for my triplets and just figured this out after I had built all of the sections. I kept thinking I must be missing something, but I came up with the exact same calculation you did. It won’t be a problem on the ends based on how it attaches to the four posts. Jen, are we missing something, or did you build this for a mattress that’s 50-52” wide?

Hi Jeremy,

We have a full size mattress in here. It’s been a few years, but I believe I allowed for an extra inch all around so it would be easier to change the sheets. I learned this after building my son’s cabin bed – the mattress was so snug inside the bed, it made it challenging to change the sheets.

Jen, after realizing this was an issue, I went back and looked at your blog post photos and compared them to the printed blueprints. If you look at your “box spring” build on your blog post, you placed the head/foot boards inside the two side runners (front/back of the bed). If that was measured at 59”, then your bed would be fine because the 2x4s from the front and back panels would still leave you with 55” inside. On your blueprints, you moved the head/foot boards to the outside, and left the same length of 59”, which leaves you with an inner space of 52” when everything is constructed. I think the blueprint way is the right way because it gives you a stronger mounting spot for your carriage bolts, but you need to add 3” to every front-to-back piece in your blueprint (ie. side railings, top side panels, box spring end pieces and cross slats). I decided to add a 2×4, the height of the front and back panels (then beveled the bottom 5.5” to make it visually end at the bottom of the box spring frame) to the front and back sides of the 4x4s. This allowed me to install those panels 1.5” farther out and still have attach points on the sides and top for both panels and, most importantly, gain those 3” back.

I followed the printed plans and the end result left an interior space front to back of 51.5″. Too narrow for a full size mattress. The pictures in the tutorial show the mattress frame being constructed in a different way than the actual PDF plans. Now I need to figure out how to fix it.

CAN U TAKE A PICTURE OF THE INSIDE

Hello Dear,

This Blog is very informative for user.

I’ve paid for the pdf but cannot figure out how to download it. Help!

Thank you Denise! You should have immediately gotten an email with the plans (sometimes they end up in the spam folder). I just re-sent them – please let me know if you still aren’t able to download the plans. Thanks again!

What paint color did you use?

Hi Tim,

I used Simply White by Benjamin Moore in a satin sheen, I believe. Hope that helps!

Love this so much! For some reason the link to the plan isn’t working.

You weren’t kidding when you said “so many things” to sand and paint. Did you prime your wood before painting or did the 3 coats provide adequate coverage?

I just wanted to drop in to say thank you, thank you, THANK YOU for all the work you put into these projects and all the extra time you put into making your blog enjoyable and easy to follow. I did a teeny tiny woodworking project at the beginning of the summer and fell. in. LOVE. with the process. That love spiraled out of control, and now I want to quit teaching and woodwork full time! (Jk… but not really.) Anyway, a lot of my love for woodworking stems from what I have learned from you and the enjoyment I get out of ready your super personable, engaging, and hilarious blog posts. So, again, thank you for helping develop in me a love (or addiction?) for woodworking!! I’ll be trying out a modified version of this lofted bed for my 3-year-old next!

Hello! I love this! I was just wondering do you have to cut the wood, or can you buy all of the parts, and then put it together? I was also wondering how would we make it fit under my 8 ft ceiling

Hi, is there measurement for a twin size?

OUTSTANDING, such a unique and simple idea that makes such a difference! You continue to AMAZE! 🙂

Youtube video is really helpful. This blog is way better than others…

Will this bed work well for a teen?

Hi there! Could I add a full size mattress at the bottom to make it a “bunk bed” situation? Also, do you have plans for this in twin size? Beautiful work!

I’m also looking at the DIY built in project, however we have a window on the head wall. Is there an option to make it not built in?

Thanks

I like this bedroom design! Children can have fun in such a room.

Wow! amazing DIY Sliding Barn Door I love the way you made it, looks like a pro. Keep it up.

Thank you for sharing this wonderful DIY idea I love it so much keep it up for more, please.