***Are you on Instagram? I am! And I often share sneak peeks of my upcoming projects there, so let’s be friends, it’ll be fun.***

Y’ALL!!! I am SO EXCITED to share my newest build with you! I’m doing a happy dance right now. Be grateful you’re not here to witness mah sexxxy man splits! #namethatmovie #pitchperfect #sorrynotsorry

Now that the weather’s warming up, the building projects are gonna be rolling in and I’m super psyched that we have a brand-spankin’ new plan to share, brought to you by the one and only Ana White! Honestly, I don’t know how she does it in freakin’ ALASKA. Superwoman, she is. I, on the other hand, am a such a wimp when it comes to working in my garage when the temps get anywhere below 40 degrees F, which is why I haven’t done anything productive since, oh, I don’t know, 1983.

But that was then and this is now. Y’all. I built this in about 6 hours! Not even kidding. It was that easy and I’m totally in love with it. This is a great beginner-level build, so if you’re timid about building from scratch and want to try your hand at it (be forewarned: this hobby can be severely addictive), this would be the perfect starter project for you.

Make your own Restoration Hardware-Inspired Balustrade Coffee Table by clicking here to download the free step-by-step plans.

Ana’s plans will have the supply list, as well as exact measurements and directions, so I’ll just share some work-in-progress photos and a helpful tip or two with you. First, I built the bottom shelf by attaching the 1×6 boards with pocket holes and wood glue. I try to make sure I’m working on a level surface so the boards are as straight as possible – it makes it so much easier when it comes time to sand, not to have to sand down inches and inches of uneven boards later.

Next, I built a frame around the bottom shelf with some 2x4s and attached block “feet” at the corners (feet not pictured). The bottom is flipped upside down so that all the screw holes are cleverly hidden underneath.

Osborne Wood is the jam, y’all. They created these gorgeous turned legs specifically for this project! And they’re super affordable at less than $30 per leg! I won’t mention how many times I lovingly caressed them during this project. (I lost count.)

The trickiest part of this build was making sure the two end blocks were straight and even on each turned leg. I concocted this little contraption to make sure everything was level, straight, and centered. Yes, I know, I am a genius and you are welcome.

And because this is my idea of working out, I had to throw (not literally) one of my husband’s kettlebells up there for good measure. I just glued the pieces together and waited for the glue to dry before I secured them with screws. One screw through the center of the top and bottom did the trick.

The legs are attached to the base with glue and and were screwed in from underneath. Crossfit, eat your heart out. (Yes, I realize 10 pound kettlebells are far from hardcore. Don’t judge.)

Then I built the tabletop the same way I built the bottom shelf. Clamped, glued and screwed. Shake and bake, Baby, shake and bake!

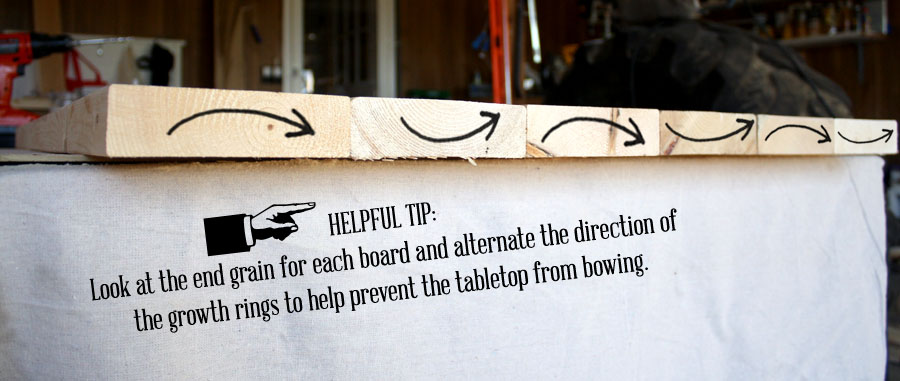

While there are different schools of thought on whether or not the information below is accurate in regards to reducing the risk of cupping/bowing boards, I usually like to alternate the direction of the end grain pattern like this:

With the builds that I’ve done, I haven’t noticed any cupping or bowing as the wood expands and contracts with the varying temperatures, so I’ll stick to what’s working for me thus far.

After attaching aprons to each leg, I placed the top on and screwed it to the aprons from underneath so that all the hardware stays hidden. And dun dun dunnnnn… we are DONE! See? Didn’t I tell you? Piece of cake, right?

Great. Now I want cake.

And now here’s the part that feels like it takes me FOR.EV.ARRR to complete: the sanding/finishing process, aka The Bane of My Existence. First, I used my belt sander to sand down the top and bottom shelves so that all the planked boards were perfectly level and smooth. Even though I’d tried my best to get them as flat as possible during the building process, without using an industrial planer, there’s going to be some slight variation from board to board.

You guys. Seriously, belt sanders are NO JOKE. I’m amazed every time I build a planked top, that a belt sander will sand down the boards so evenly that you can easily slide a salt & pepper shaker across the table. I bought my Ryobi belt sander from a pawn shop for $11. Whoop whoop! LOVE it.

After I was satisfied with that, I followed up with my palm sander fitted with 120- then 220-grit sandpaper. Then I vacuumed up the sawdust and wiped everything down with a very slightly damp rag. I stress “very slightly damp” because I wanted to remove the leftover dust and debris, but didn’t want to raise the grain after I’d worked so hard to smooth everything down like buttah.

I chose Minwax’s Ultimate Wood Stain in Special Walnut to stain this bad boy. I just took a clean rag, dipped it into the stain, then working in small sections, rubbed it into the wood, in all directions, usually in circular motions until it’s all soaked in. Wax on, wax off, Daniel-son style. #namethatmovie

After the stain had a full 8 hours to dry, I tried Minwax’s Wipe-On Poly for the first time ever then kicked myself for not trying it sooner. Hello? Has anyone used this stuff before? It’s magic. You just wipe it on with a rag. No bubbles, drips, or streaks! What! Shut the front door.

Yes, it’s not as durable as regular polyurethane, but after 3 coats, it was more than enough protection for a coffee table. I used a 220-grit sanding block in between each coat. I wouldn’t recommend this stuff for a dining table, or anything that would be used more frequently, but for an occasional table? Abso-freakin-lutely. It was soooo easy to apply and so quick too! Only about 2-3 hours of dry time in between coats. Hallelujah, praise Jesus!

Then, just for kicks (and even more protection, because I’m redundant like that like that), I applied Annie Sloan’s soft wax just on the tabletop so that it felt really soft and smooth to the touch. Love, love, looove that buttery hand-rubbed finish.

Gahhhh… I am dying over these gorgeous turned legs. Dying. Dyyying. I’m dead.

Did you spy that rustic little end table over there? Another Ana White plan, of course! Click here to learn more about that DIY project.

Ahhh… thank you Osborne Wood. I love you. Will you marry me?

So what do you think? Think you can build this for hundreds of dollars less than the Restoration Hardware version? I know you can! Go here for the plans and get ‘er done! And thank you for working with me on this one, Ana! You are the bomb dot com.

Thanks for reading, friends! If you enjoyed this post, feel free to pin and share it! Catch y’all on the flip side. Peace out.

Tools Used:

- Measuring Tape

- Speed Square

- Carpenter’s Pencil

- Saw

- 18v Cordless Drill

- Kreg Jig K4

- Clamps

- Belt Sander

- Palm Sander

Budget Breakdown:

- Lumber: $63

- Osborne Wood Turned Legs: $28.03 each

- Finishing Supplies: $33

- Screws, glue, misc: already owned

Total Cost: $208.12

I really love this. May have to show this to my guy. Great job!

Loving this coffee table! You’ve totally inspired me to take this project on! I am very much a beginner to carpentry, but I’m feeling so empowered as I go through the steps, and my coffee table starts to look like a coffee table!!! 🙂

When you did the staining, did you use a pre-treatment on the wood before the actual staining?

Thanks so much for your help!

Thanks for the sweet note, Shelby! No, I didn’t use pre-conditioner on this table. Usually, I would, but this time, I wanted the finish on the table to look as ‘reclaimed’ and ‘imperfect’ as possible. Good luck and happy building!

Stunning! I’m green with envy over here. If I were ever to replace my coffee table, I’d want something just like that.

Where did you purchase the rug underneath? I just repaired all the walls in my house Charcoal by Pantone, but my floors are an imported multi brown tone of Italian tile, this rug would help marry the two colors as the shades are exactly what I’m dealing with! I would be so appreciative to have this info. Thanks in advance. Btw beautiful redo. You are so talented!!

The rug is from Rugs USA, here: http://www.rugsusa.com/rugsusa/rugs/rugs-usa-trellis/charcoal/200HJHK24A-26010.html

Beautiful table! Great work!! Thank so much for share it!!!

Hi! I am not sure if you already received and answered this question, so I apologize for the redundancy…

Did you use Minwax Wood Conditioner before staining it? I read it makes the stain easier to apply, and helps to avoid blotchy spots. Your finish looks so even and smooth. Just curious. My husband just built this gorgeous table (knotty pine), and I don’t want to mess it up!

Thank you,

Luila

Thanks Luila! I’ve used the pre-stain before the past and have been really happy with the results, especially when working with pine or spruce, but for some reason, I didn’t use the pre-stain when finishing this table. Not sure why, but lucky it turned out okay!

This is amazing!!! I tried to makeover a coffee table a while back with paint and decoupage. And it was ok, but I’m a little disappointed in it tbh. This though.. I think I can do this (I took shop in college.. Surely something stuck). =D And it’s so beautiful (and so much cheaper than the RH version). It’s the kind of table that I drool over in people’s houses that are so put together and have gorgeous furnishings everywhere. I’m just now realizing that there’s no reason I can’t make most of that stuff myself thanks to posts like this.

I just placed my order for the coffee table legs off Osborne’s site! Can’t wait for them to get here! I’ll definitely post it on my blog when I’m done and link back here. Thanks to you and Ana for putting these plans together for everybody! A true inspiration!

Great Coffee table! Wife wants me to make one, but I went to Osborne’s and seen they have a few different materials for legs. Which did you use?

I chose the knotty pine species.

What type of wood did you use on both the planks and from Osborne?

Thank you … love this table

Hi Annette,

I used knotty pine for the Osborne legs and douglas fir for the rest. Thanks!

What size turned legs did you purchase?

Hi Annette,

These are the exact turned legs I used: https://www.osbornewood.com/1332.aspx

Table is gorgeous! I’m planning on building this but with 12″ boards for the top and 6″ breadboards. Suggestions on how to support these bigger planks?

I am new to DIY and I am planning to buy furniture for my first ever home… Yay!! I found this post and I am absolutely inspired. like everyone else I love love love RH. I am going to give this a try. If mine turns out half as gorgeous as yours I will consider it a success. Thank you for writing such an inspiring post.

Hi! I’ve never done any woodworking in my life, but if you can do it, I can do it! I am TRULY inspired by so many women commenting!

Here are my newbie questions:

1.) How do you pick your lumber? Is there a furniture grade? Premium grade? Does furniture grade have all those ink marks on it and how do you get it off? 2.) Is there a basic woodworker’s tutorial that you would recommend? Do you have one yourself……or should I just get out there and try it?

3.) What kind of work table did you use?

I’d like to know what I’m talking about before I go to Home Depot or Lowe’s. Even when I DO know, I’m often treated like “just a woman”. There have been a few times I’ve taught the guys a thing or two! 🙂

Thanks for your help!

Hi Laurel,

I spend hours sifting through the lumber pile, trying to find the straightest boards I can find. I usually use either pine or spruce – this is framing lumber. When I want to upgrade, I use soft maple or another hardwood – this is furniture grade lumber.

You can sand off the stamps.

The workbench I made and use is here: https://jenwoodhouse.com/diy-workbench-2

Good luck and happy building!

Thanks, Jen.

So for furniture making – specifically – you would recommend maple? Any other specific wood type you would recommend for coffee/end/kitchen tables?

Hi Tristan,

The wood species you choose would depend on the actual piece, what look you’re going for, etc. I like to use maple for dressers and nightstands, but don’t mind using Pine for more rustic pieces, like a farmhouse table, for example. For coffee, end, kitchen tables, depending on what kind of look you want and the kind of money you’d want to spend, pine, spruce, maple, poplar, oak, or walnut would all work well. Hardwoods like oak and walnut are generally more expensive than softwood like pine or spruce. Hope that helps!

Hi Jen!

Did you rip your board through table saw to remove the router dedicated edges or did you go with them as is?

Hi Jessie,

Yes, sometimes I do rip the curved edges off the boards (on a table saw), just to square them up. I didn’t do that on this balustrade table though.

Question regarding this table; kitchen table, entry table…do you Polly the whole project ot just the tops??

Hi Tristan,

I apply poly on the entire project.

Awesome projects. Created it using one extra board for 5ft by 3 1/2 ft. Painted one light coat of grey door paint letting some wood show. Legs are well worth it for the look