*This post is brought to you by The Home Depot.

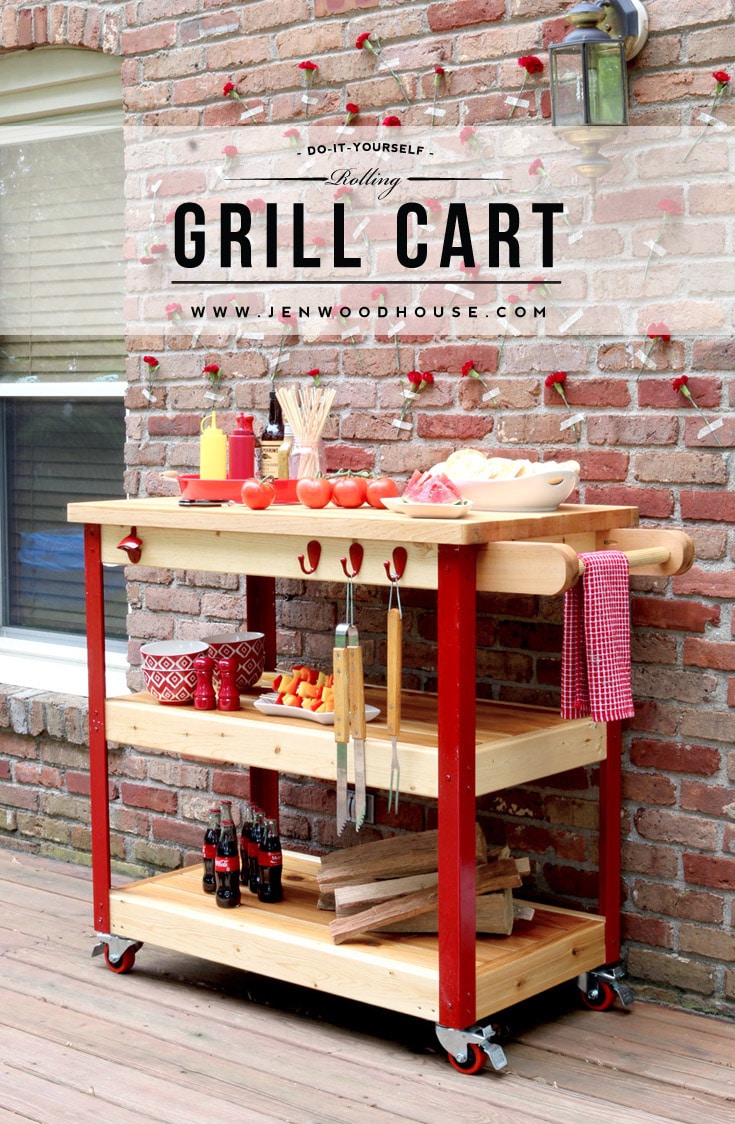

Hi friends! I’m super excited to share my latest project with y’all! And what perfect timing, right? Father’s Day is quickly approaching. Wouldn’t this rolling grill cart make the perfect gift for your favorite Grill Master?

My dad is a USC grad (and rabid fan), so I had no choice but to paint the metal pieces Trojan red! I built this cart out of metal, cedar, and reclaimed butcher block. You guys. I had no idea that butcher block was so stupid expensive! But I totally lucked out on this one – I snagged this butcher block from my neighbor’s garage (he gave me permission – relax), who rescued it from a local bakery that was shutting down. Isn’t it beautiful? It was an enormous countertop that they used to bake bread on. Well, not bake, but you know what I mean… cut, slice, knead, pound, hammer… what? I’m a builder, not a baker. Whatevs.

The butcher block was so thick and massive, that I cut out the piece I needed, then had to cut that piece in half to fit it into the planer. We had to send it through a planer quite a few times because the wood was bowed, dirty, and gross from sitting in a garage for ages. And it’s still this thick even after planing the crap out of it. When we were cutting and planing it, the wood smelled like bread. Isn’t that amazing?

Seriously. Look at this thing. Ugh, so beautiful, I can’t even deal. Butcher block is my new favorite building material. I want to butcher block ALL THE THINGS!

(Did she just use ‘butcher block’ as a verb? Yep. I did. Boom.)

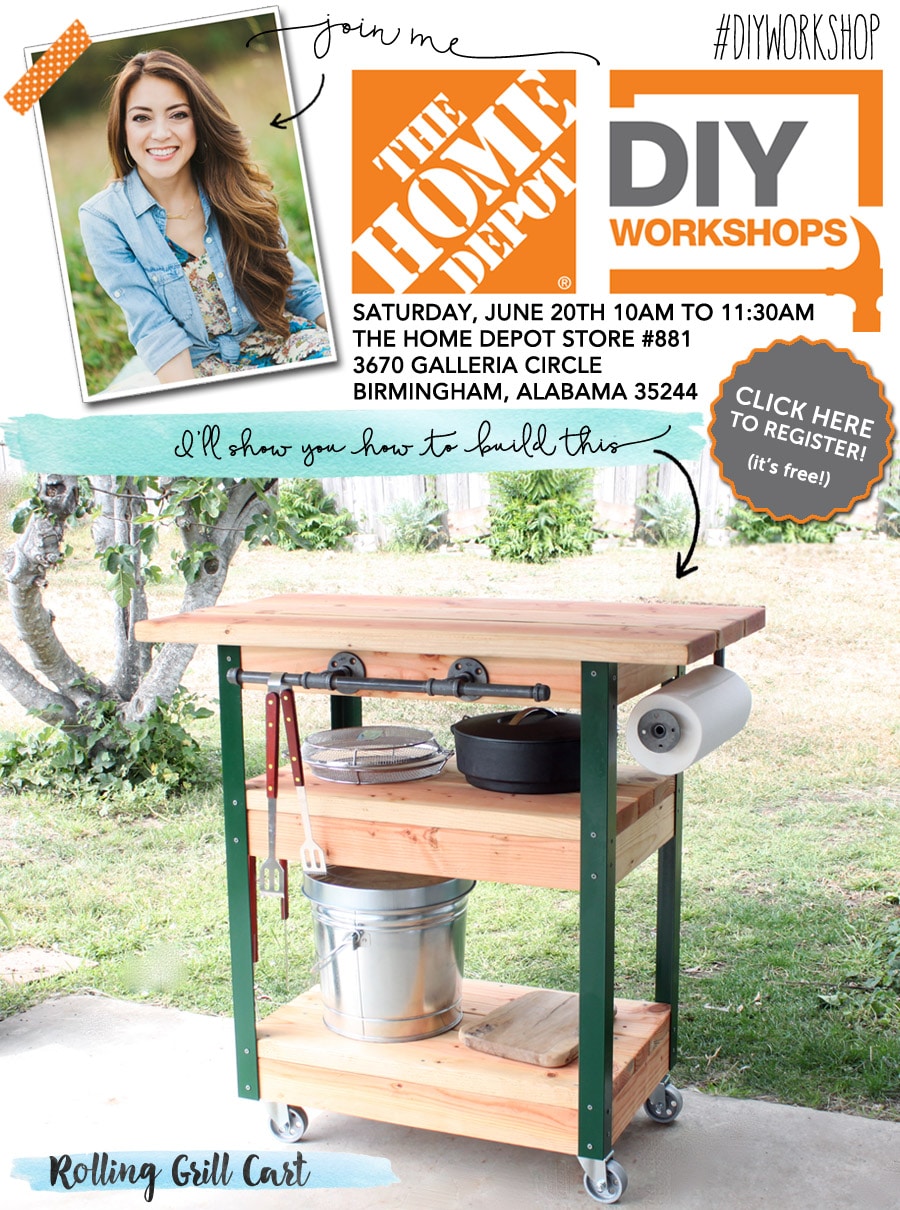

Here are the workshop deets:

Where: The Home Depot Store #881

3670 Galleria Circle

Birmingham, Alabama

When: Saturday, June 20th

Time: 10:00 a.m. to 11:30 a.m.

Cost: Free!

- Jaime – That’s My Letter – Store #1286 – 4405 Milestrip Road, Buffalo, NY

- Katrina – Chic Little House – Store #1532 – 3870 Quebec Street, Denver, CO

- Chris – Man Made DIY – Store #4706 – 11616 Aurora Avenue North, Seattle, WA

- Michelle – Decor and the Dog – Store #2104 – Southdale Shopping Center, Des Moines, IA

You don’t want to miss this event – it’ll be exactly one ton of fun. REGISTER HERE and let us you know you’re coming! We’d love to meet you.

The grill cart was designed by Ben Uyeda of Homemade Modern, so we’ll be building his version at the workshop. Here are the plans for his grill cart. He even put together a super helpful how-to video! If you’d like to build my customized version, I’ve drawn up the plans for you.

*This post contains affiliate links. To read my full disclosure policy, click here.

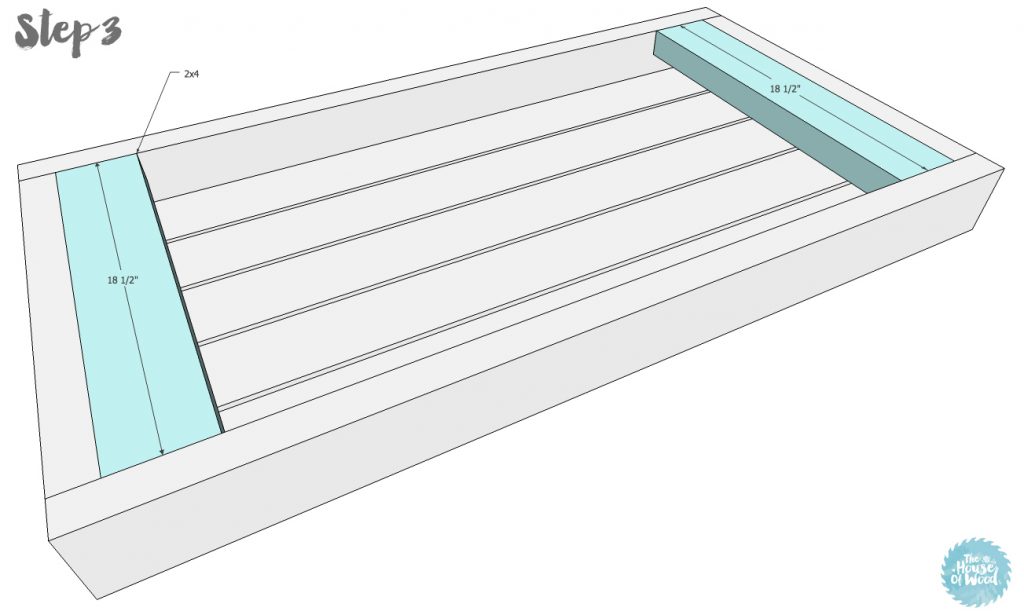

First, you’re going to build three frames. These will be your three shelves. Build the frames by pre-drilling pilot holes and attaching with 2-1/2″ deck screws. When drilling close to the edge, you always want to pre-drill your holes to avoid splitting the wood.

Next, I used pocket hole joinery to attach the 1×4 boards to the frames so that the screw holes are hidden underneath. I use this Kreg Jig model to drill the pocket holes. Also, I used a 1/4″ scrap piece of plywood as a spacer, to space the boards out evenly. I just love the variations of color and tone in cedar, don’t you?

After all the holes were drilled, I sanded the rust and blemishes off the angle irons with a 150-grit sanding block. Even though I bought the angle irons new, they had some rust spots and a whole lotta grossness on them. Then I sprayed them down with some brake cleaner. My husband uses this stuff to clean his firearms, so we had some on-hand.

After the angle irons are cleaned and prepped, they’ll need to be painted or sealed to prevent rust and rot from moving in. I sprayed on some primer and let it cure. After the primer was dry, I sanded the angle irons to smooth out the surface, then sprayed it with 2-3 coats of red spray paint. It says on the label that it “stops rust” so I’m taking their word for it. The reviews were good too, so I went with it.

To attach the angle irons to the wood, I used 2-1/2″ deck screws. You’ll want to be aware of where the other screws are placed so you don’t have a hardware collision. Don’t ask me how I know. Ah, foresight, you elusive creature you.

Also, notice I drilled 1-1/2″ pocket holes facing up, into the top frame. This will be how I attach the butcher block top in later steps.

My friend Brad from Fix This Build That makes and sells these gorgeous cutting boards, so I hit him up with a bunch of questions on how to properly join butcher block. Had I known how easy it is to make biscuit joints, I would have done it sooner. Oh my goodness, you guys. This is not rocket surgery. You are going to flip out when you see how easy it is. Watching this video was super helpful.

I bought this biscuit joiner after reading the great reviews on it. Sure, there are bigger and better ones out there, but this one was the right price point and it did the job perfectly well. Basically, you hold the tool like so and push it into the edge of the wood. The blade cuts little slots into the wood and you use wood biscuits to hold the joints together, along with a healthy dose of wood glue.

I had a couple of bar clamps already, but for this project, I bought two of these heavy duty parallel clamps. They certainly aren’t cheap, but they are pretty dang awesome so I’m happy to have them in my workshop. I plan on investing in a few more soon when my husband is okay with it.

Next, I added a handle to pull the grill cart around with. I cut these pieces with a jigsaw, then used a 1-1/4″ spade bit to drill the hole for the dowel. Clamp it together and drill through both pieces to ensure the holes line up.

Although I used weather-resistant cedar lumber, I wanted to make sure the cart was protected by some kind of finish. I chose to use tung oil on the bottom two shelves, which really brought out the beautiful grain and color in the cedar. To the top, I applied several coats of food-safe butcher block oil.

Love this project? Want to learn how to build it for yourself? Come to one of the DIY Workshops at The Home Depot! It’ll be awesome. I dare you to build this grill cart and put your own spin on it! Oh, yes. The gauntlet has been thrown down. I’d love to see your customized version, so if you build it, be sure to share it on Instagram, Twitter, or Facebook and tag me with #jenwoodhouse and #DIYWorkshop so I can see it!

Feel free to pin and share this project using the image below. Have a great Father’s Day weekend you guys! See you out there.

Pin for later!

*I acknowledge that The Home Depot is partnering with me to participate in this Workshops Program. As a part of the Program, I am receiving compensation in the form of products and services, for the purpose of promoting The Home Depot. All expressed opinions and experiences are my own words. This post complies with the Word Of Mouth Marketing Association (WOMMA) Ethics Code and applicable Federal Trade Commission guidelines.

can you please send me the “recipe” for this wonderful cart? maybe im overlooking it, but i can’t find the dimensions for your original cart– with the red decor. I don’t know what those metal supports are called? and the lockable casters?

And what kind of screws,ETC–what tools?

I will gladly pay for the plans, also.

Thankyou!

Hi Patricia,

Thanks! Just click the gray button that says “Download PDF plans” and it’ll bring you to a PDF file, which you can save and/or print. The metal parts are angle iron and the casters are just regular 3-inch locking swivel casters. The materials and tools needed are listed in the PDF plans. Hope that helps!

Did you encounter problems using a 2 1/2 inch softwood pocket screw to secure the hardwood butcher block top?

If you don’t mind a slightly shorter grill cart with black legs, Rockler Woodworking and Hardware has 32″ legs (#60749) with the holes already in the bottom of the legs to accept the casters (#47034) which would make the project some what easier. I’m not sure if you could paint the legs as they have a baked on finish. For a novice, this would help, and if you needed it higher you could add the 3″ riser blocks (#44836) to bring it up to 35″.

Hi Jen

Cart looks beautiful. What SW did you use to create the initial design and mark measurements before you went into creating frames?

Avi

Thank you for free plans 😁

Hi, love the plans! Question – what metal should we use for angle irons? Steel and aluminum are both available in store. Also how strict should we be about the 2inches exactly? Would 1.5 inches width be sufficient for the angle irons? We are having issues finding exactly the right pieces.

Thanks in advance for any tips!