Hello friends! Welcome back!

Okay, so here’s where we left off last week: the large drawers are done (happy dance!) so now we’re moving onto building the small drawers. Are you ready? Hold onto your hats, ladies and gents, because this is going to be so stupid simple it’ll have you going, “well, duh!”

- Part One: Building the Carcass

- Part Two: Building the Large Drawers

- Part Three: Building the Small Drawers (you’re here!)

- Part Four: The Final Details

*This post contains affiliate links. To read my full disclosure policy, click here.

I went back and forth on how to build the small drawers. I took a few days and just mulled it over. I quite enjoy mulling, actually. I did it on the couch, I did it in bed, I did it in the car… you can do it just about anywhere. Get your mind out of the gutter – I know what you’re thinking, you.

Since I used these hardwood drawer slides for the large drawers, I wanted to use wood slides for the small ones too, but I didn’t want to lose any more valuable real estate in the drawers. In other words, the small drawers are shallow enough as it is and these center mount slides would’ve made them even shallower. That’s a weird word, isn’t it? Shallower. I’m inclined to say “more shallow” but “shallower” is correct. Thanks Merriam-Webster.

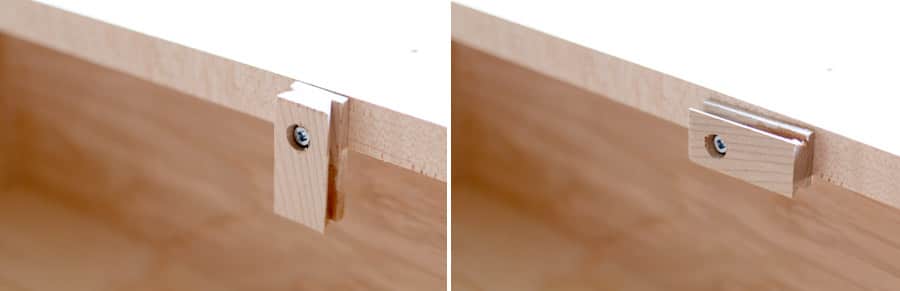

And I couldn’t use metal drawer slides since I ran my mouth off about how important it was to use wood slides with furniture and blah blah blah. So after a bit of searching, I found this video and it was the perfect solution. In fact, I wish I would’ve found it earlier because I would have built the large drawers like that dude did and saved myself a bucket full of tears. Doh!

First, I measured the space where the small drawers would go and built the box to fit. I used 1/2″ plywood for the drawer fronts, backs, and sides and routed the top edges with a 3/8″ roundover bit. I drilled 5/8″ pocket holes and constructed the box with 1″ pan-head pocket hole screws.

Read the complete tutorial:

- Part One: Building the Carcass

- Part Two: Building the Large Drawers

- Part Three: Building the Small Drawers (you’re here!)

- Part Four: The Final Details

And here’s a sneak peek of what’s to come (spoiler: it ain’t pretty):

Hi Jen, looking forward to making this dresser and was wondering if part four and the plans will be posted soon. Great site, and thanks in advance.

Any update on finalizing these plans… Would love to build this dresser. Thanks!

You could attach the top sides with pocket hole screws from the outside if you wait to put the top piece of 1×4 trim on the sides and hid the pocket holes under the trim. Just a suggestion, and what I plan to do when I build mine.

Thanks for a great tutorial and a great set of plans!