Welcome back, friends! Thanks for sticking with me through this long, drawn-out DIY dresser tutorial. Here’s where we left off:

Read the complete tutorial:

Read the complete tutorial:

- Part One: Building the Carcass

- Part Two: Building the Large Drawers

- Part Three: Building the Small Drawers

- Part Four: The Final Details (you’re here!)

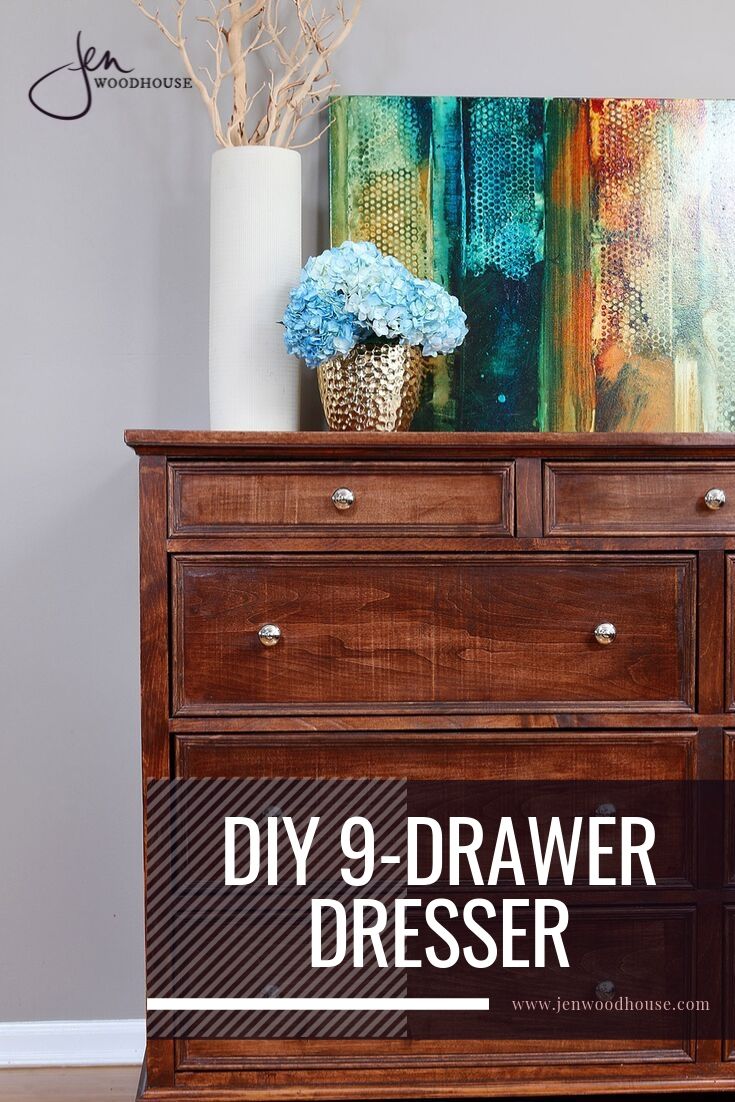

Wanna take a peek at how it finally turned out? Spoiler alert: all the blood, sweat, and tears were totally worth it.

I cut the 3/4″ cove moulding to size, mitering the ends at a 45º angle then glued and nailed them to the side panels. It’s better to cut the trim to fit, instead of using a measuring tape. Cut it a bit long, then trim it down until it fits snugly. I also attached cove right under the table top and all along the bottom.

Well at least we know this thing is built solid like a rock. #overbuildersanonymous

After I attached all the drawer faces (correctly!), it was time to add the decorative trim. Once again, hold up the trim, mark it, and cut it to fit, mitering the ends at 45º. I used painter’s tape to hold the trim in place while the glue dried. Then I went back and shot a few brad nails in there just for good measure.

Next, I attached the bun feet the same way I did here, using my hanger bolt/tee nut combination then stapled the back panel on. I finished it the same way I finished my dad’s printer table, using stain, glaze, toner, and polyurethane. The in-depth finishing tutorial can be found here.

And after months and months of blood, sweat, and tears, I’d like to take a moment to revel in the fact that this beast is finally (fiiiiinally!) done:

Of course, my brother- and sister-in-law are wonderful, loving people who would never think such cruel thoughts, but it’s amazing how my own insecurities will overrun logic and truth. And though this dresser is not perfect, it’s the absolute best I could offer at this point in my skill level.

You’ll find the building plans and tutorial for the matching nightstands here.

Donny and Carisa, I love you guys.

Pin it for later!

I am studying the plans for this dresser and can’t wait to start building it. Looking at the material and cut lists I see it calls for seven 1″x3″x8′ pieces to produce ten 63″ long rails. The linear feet might be there, but it’s impossible to get ten solid rails from seven 8′ boards. You need ten boards, hopefully 6′ long.

Other than that I’ve decided to use cleats in the cabinet and grooves on the drawer sides for the smaller drawers to avoid metal hardware, and I’ll probably attach the trim strips to the sides before attaching them to the base. I also worked out that it takes around 100′ (plus extra jik) of molding to do all the trim so you’ve given me an excuse to start making my own molding. Save some cash and have some fun.

This DIY dresser project looks amazing! I love the step-by-step instructions and the tips on choosing the right wood. Can’t wait to give it a try! Thanks for sharing!

I loved this post! The step-by-step instructions were super clear, and the tips about wood choices were really helpful. Can’t wait to try building my own dresser now!

This is such a fantastic guide! I love how detailed the instructions are, making it seem doable even for a beginner like me. Can’t wait to try building my own dresser—thanks for the inspiration!