A quick and easy tutorial on how to hang batt insulation for beginners.

We’re in the midst of a guest bathroom renovation and the room is starting to come back together. It always gets worse before it gets better, right? That’s what I keep telling myself anyway. When we demo’d the walls and the shower stall, we tore out all the old insulation. Most of it was loose insulation that just fell out and made a mess everywhere, so today, it’s insulation day!

We’re hanging insulation the easy way with the help of Arrow Fasteners. If you recall, I’ve partnered with Arrow Fastener to bring you several DIY projects this year! Did you see the DIY Pin Board I made a few months ago? We even filmed a video!

How to hang insulation

How to hang insulation

Tools:

- Arrow cordless staple gun

- Arrow hammer tacker

- 1/4-inch staples

- Scissors or utility knife

- Safety glasses

- Dust mask

- Gloves

Supplies:

- R-13 batt insulation (for walls)

- R-38 batt insulation (for attics)

Insulation R-Value: What Does It Mean?

Insulation R-Value: What Does It Mean?

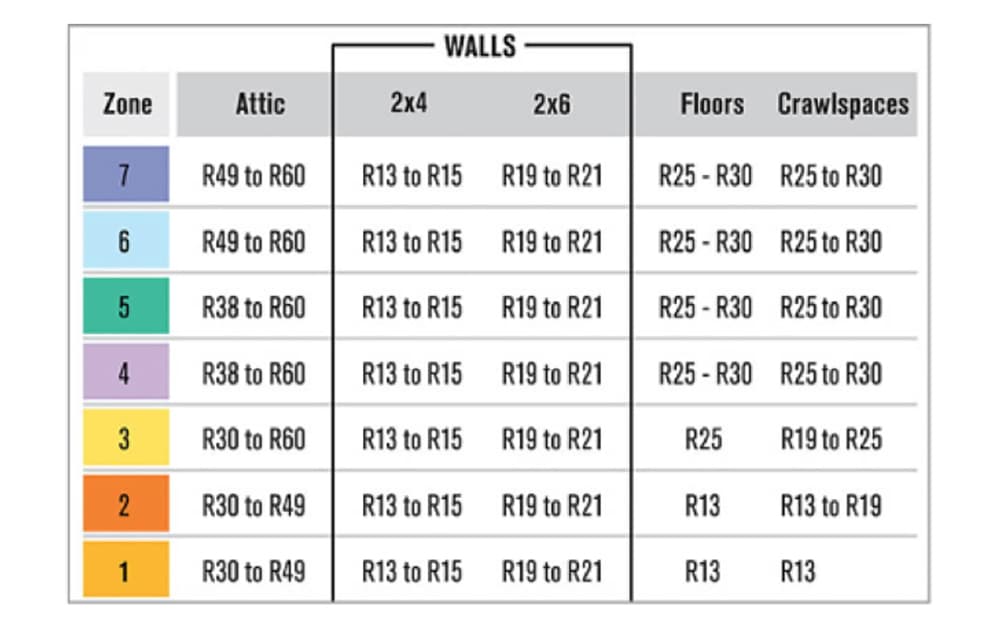

The R-value stands for “resistance to heat flow.” The higher the R-value, the greater the insulation performance. For our area, R-13 batt insulation is recommended for interior walls and R-38 for attics, since we need the extra shield from the extreme heat and cold coming from our attic. You’ll want to check your local code for the insulation recommendations in your zone. Here’s a handy chart.

Let’s talk safety gear. When handling this material, you definitely want to wear a dust mask and gloves (which is what I’m doing here), as well as safety glasses and long-sleeves (those safety glasses are doing so much good on top of my head, aren’t they?) because this stuff can be itchy if it gets on your skin. Luckily, I didn’t have much insulation floating about that it irritated my eyes or skin, but if you’re sensitive to these things, a dust mask, gloves, long sleeves, and safety glasses are what’s recommended.

Guest Bathroom Renovation

- Part 1: Design Board

- Part 2: Demo Day!

- Part 3: Plumbing Rough-In and Floor Leveling

- Part 4: Insulation and Cement Board Installation

If you’re in the market for either of these tools, be sure to check out ArrowFastener.com.

*This post is in partnership with Arrow Fastener and contains affiliate links. All efforts and opinions are my own. To read my full disclosure policy, please click here.

How to hang insulation

How to hang insulation

As a former homebuilder we always stapled insulation to the front of the studs. Then covered with clear plastic sheeting. Stapling on the inside of the studs compresses the insulation and reduces the R value. It’s a personal preference

Is there a code on which way side or front of stud I prefer the face of the stud we live in Virginia Beach Virginia

Staple the paper strip to the face of the stud facing the room, not to the inside of the stud as pictured